In construction, time is tied directly to money, progress, and trust. A strong construction schedule is more than a calendar; it’s the plan that keeps people and materials moving. When scheduling works, jobs stay on track. When it doesn’t, delays can cost thousands and slow everything down.

Build Data Centers Faster with SmartRock® Long Range

According to Outbuild, 87% of firms have had project delays, often caused by poor schedule management and bad communication. These delays increase costs and strain teams. The Construction Management Association of America (CMAA) confirms that delays can lead to legal claims and rising costs.

This blog will explore construction scheduling from foundational principles to advanced methods, common challenges, and technology-driven solutions that improve concrete quality, optimize and streamline operations from planning through execution.

Core Principles of Construction Scheduling

A good construction schedule starts with a strong foundation. These basic principles help teams plan ahead, stay organized, and keep the project moving.

Start With a Clear Scope and Goals

Before you build a timeline, define the full scope of the project. What exactly needs to be done? When does it need to be finished? Clear goals help prevent surprises. For example, if a school must open by September 1, that date drives the concrete pour management timeline.

Break the Project Into Smaller Tasks

Use a Work Breakdown Structure (WBS) to divide the project into trackable tasks. A task like “pour concrete” may be part of a larger phase, such as “structural work.” Optimal tasks last 5–10 days, making them easier to assign and monitor. This approach also helps teams plan post-tension vs conventional slab operations and anticipate post-tension time requirements.

Connect Tasks Logically

Identify dependencies between tasks. Some work must finish before others begin. This logic defines the critical path, which dictates the project finish date. Proper sequencing ensures accurate concrete schedule management and avoids delays in critical jobsite operations such as cycling formwork or removing formwork.

Use Realistic Time Estimates

Use real data or past experiences to estimate how long each task takes. For risky or unknown tasks, consider three estimates: best case, worst case, and most likely. This approach helps manage post-tensioned concrete strength timelines and ensures the right window for concrete quality testing.

Update and Adjust Regularly

Schedules are dynamic. They should be reviewed and updated often. Cloud tools like Autodesk Build, Procore, and Giatec 360 allow everyone to access the latest version and make updates in real time, allowing teams to monitor IoT concrete strength and IoT concrete temperature to optimize cycling formwork and overall workflow.

Top 5 Scheduling Methods

Choosing the right scheduling method can make or break a project. Each method has its strengths and best use cases. Some are great for managing big, complex builds, while others work best for jobs with repeating tasks or fast-changing conditions. Here are five of the most widely used construction scheduling methods, and how they help teams plan better, react faster, and deliver results.

1. Critical Path Method (CPM)

CPM is one of the most common scheduling tools in construction. It breaks down a project into tasks, shows how those tasks connect, and identifies the “critical path”, the chain of tasks that determines when the project will finish. If anything on that path is delayed, the whole job gets pushed back. CPM helps teams see where to focus their efforts and where there’s flexibility. It’s ideal for large projects with many moving parts, like hospitals or highways. CPM helps plan concrete pour management, post-tension versus conventional slab workflows, and removing formwork sequences. The method works best when regularly updated to reflect real progress and shifts in the field.

2. Program Evaluation and Review Technique (PERT)

PERT is similar to CPM but adds more detail about time uncertainty. Instead of giving each task just one timeline, it uses three: best case, worst case, and most likely. This makes PERT a good choice for projects where teams face unknowns, like new technologies or custom designs. It gives a better estimate of overall project time, especially during early planning. However, it’s more complex and rarely used on typical job sites.

Interested in how schedule uncertainty impacts budgets and risk? Download our guide for Construction Cost Control Strategies now!

3. Last Planner System (LPS)

LPS comes from lean construction. Instead of planning everything top-down, it lets the people doing the work, like trade foremen, create weekly plans based on real conditions. This makes schedules more realistic and flexible. Teams meet regularly to update plans and clear roadblocks. It’s especially useful in fast-moving or design-build jobs where things change quickly, and real-time concrete monitoring is critical. While LPS requires strong team communication, it builds trust and keeps everyone focused on what’s doable, not just what’s ideal.

4. Line of Balance (LOB)

LOB works well on projects with repeating tasks, like apartment buildings or long road sections. It shows how work moves from one unit or section to the next over time. This helps crews stay balanced and avoids stacking trades on top of each other. For example, if framing crews are faster than plumbing crews, the chart makes that clear so the team can adjust. LOB is very visual and easy to follow but doesn’t work as well for jobs with lots of unique tasks.

5. Software-Based and Hybrid Methods

Most teams today use digital tools to schedule. Primavera P6 and Microsoft Project are long-time favorites for big jobs. Newer platforms like Procore and Autodesk Build add features like mobile updates, dashboards, and real-time field data. These tools let teams blend methods. For example, using CPM for the big picture and LPS for weekly planning. When done right, hybrid scheduling gives control of CPM with the flexibility of lean. But it works best when teams are trained and committed to regular updates.

Building an Accurate Construction Schedule: 9 Steps That Work

A strong construction schedule isn’t just about dates, it’s about getting the right tasks done at the right time with the right resources. From planning the first concrete pour to removing formwork, every step matters. These nine steps help project teams build a clear, flexible plan that stays useful from kickoff to close out.

1. Define Scope and Milestones

Start by getting clear on what you’re building and when it needs to be done. Write out the scope, what’s included, what’s not. Then, define big milestones such as:

- Site ready (excavation complete, utilities installed)

- Foundation poured and cured

- Structure topped out (including post-tensioned slabs)

- Occupancy permit issued

Milestones act as anchors for the concrete schedule, helping teams track progress. Early clarity reduces disputes and aligns stakeholders from the start. Incorporating concrete monitoring systems at these milestones ensures that concrete quality targets are being met before moving to the next phase.

2. Build the Work Breakdown Structure (WBS)

Break the project into manageable pieces using a Work Breakdown Structure (WBS). Start broad with major phases like:

- Sitework

- Framing

- Mechanical, Electrical, and Plumbing (MEP)

- Concrete work (including cycling formwork and post-tension time)

Then break these into smaller tasks that are trackable and assignable, typically work lasting 5–10 days. For concrete pour management, tasks might include: formwork setup, pouring, IoT concrete strength monitoring, curing, and stripping forms. A detailed WBS improves concrete schedule visibility and ensures no steps are skipped.

3. Link Task Dependencies

Identify which tasks rely on others. This step builds the logical flow of the schedule and uncovers the critical path, the sequence of tasks that directly impact the finish date. Examples include:

- Framing must finish before drywall installation.

- Post-tensioned concrete strength must reach target levels before removing formwork.

- Cycling formwork for multiple floors must follow a strict sequence.

Understanding dependencies prevents bottlenecks and ensures timely completion. Modern tools allow linking IoT concrete temperature and strength data directly to task milestones, keeping the schedule dynamic and actionable.

4. Estimate Durations

Each task needs a realistic time frame. Use past project data, vendor guidance, and trade knowledge to determine durations. For uncertain tasks, apply three-point estimates:

- Optimistic: best-case scenario

- Pessimistic: worst-case scenario

- Most likely: expected duration

This gives better insight into possible delays and helps manage expectations.

5. Assign Resources

Once durations are set, they allocate crews, equipment, and materials. Resource loading ensures no conflicts occur. For instance:

- Two crews sharing the same lift or pump

- Limited availability of skilled trades for post tension versus conventional slab work

- Coordination of concrete monitoring devices for simultaneous pours

Resource planning prevents delays, reduces cost overruns, and ensures the team can adhere to the planned concrete schedule.

6. Check for Risks

Before finalizing the schedule, scan for problems. Meet with field teams and trade partners to identify issues like long lead times, inspection delays, or weather risks. Use Monte Carlo simulations or simple checklists to test “what-if” scenarios and build in buffer time when needed.

7. Set the Baseline

Once the team agrees on the plan, lock it in as the baseline. This becomes the version used to track progress. Add notes explaining logic ties, holidays, and assumptions. Upload it to a shared system like Procore or Autodesk Build, so everyone works from the same version.

8. Monitor and Communicate

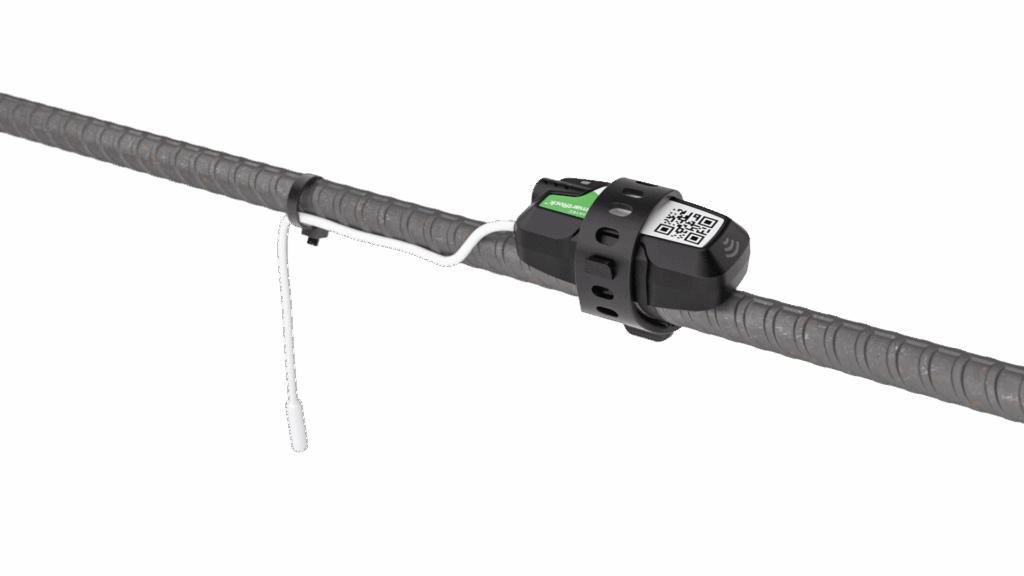

Update the schedule regularly, weekly or biweekly. Use field apps and dashboards to log progress. For example, Giatec SmartRock® sensors can confirm when concrete is ready, and the schedule updates instantly. Use lookahead views, milestone charts, and color-coded Gantt visuals to keep everyone aligned.

9. Adjust During Execution

No project ever runs exactly as planned. Use short-term planning tools like Last Planner or digital boards to adjust in real time. If something runs late, you can re-sequence other work or add a crew. The faster you respond to change, the better your chances of finishing on time.

Want to learn more about optimizing your construction projects? Read our Construction Management 101 blog here!

7 Key Scheduling Challenges and How to Fix Them

Even with a good plan, construction projects often face delays. Weather, scope changes, or communication gaps can throw off even the best schedules. But many of these issues can be avoided, or at least managed, with smart planning and real-time tools. Let’s take a look at seven common challenges and how to fix them.

| Challenge | Impact on Construction Schedule | Solution / Tools |

| 1. Lack of Real-Time Tracking | Delayed updates cause tasks to slip, slowing concrete pour management and progress monitoring. | Use SmartRock sensors to track concrete strength and feed live updates into the schedule. Platforms like Autodesk Build or Procore keep the plan current. |

| 2. Scope Creep & Uncontrolled Changes | Adding work without adjusting the schedule affects key milestones and can delay post-tensioned concrete tasks. | Simulate changes with schedule tools like Autodesk Schedule Compare. Always update the schedule and include buffers for critical activities. |

| 3. Poor Communication Between Teams | Teams may work from outdated plans, causing rework or delays in formwork or concrete pours. | Centralize schedules on shared platforms, use notifications, and hold weekly lookahead meetings to align crews. |

| 4. Schedule Drift / Missed Float | Minor delays accumulate, affecting the finish date or critical slab work. | Monitor floats with SmartPM and use visual tools like Last Planner boards to catch early signs of drift. |

| 5. Conflicts Over Shared Resources | Two crews needing the same equipment can stall work and disrupt timelines. | Use resource-loaded scheduling, run coordination meetings, and tools like MixPilot™ to prevent rejected loads. |

| 6. Human Errors & Bad Data | Mistakes in task durations or sequencing can derail milestones. | Automated checks (SmartPM, DCMA 14-point) detect errors. Peer reviews and lessons learned to improve accuracy. |

| 7. Lack of Coordination Across Trades | Separate schedules for GC, subs, and suppliers cause overlaps and inefficiencies. | Build a master schedule using 4D BIM or color-coded lookaheads to align all stakeholders. |

What Owners Want: Clarity, Simplicity, and Visuals

Owners want to know: Is the project on track? Will it finish on time? They don’t need every task or detail; they want big-picture updates that are easy to understand. A clear construction schedule builds trust and speeds up decisions. Here’s how to meet that need:

| Owner Priority | How to Deliver | Tools & Examples |

| Milestones, Not Microtasks | Highlight major events: foundation start, roof installation, opening day. | Autodesk Build |

| Visuals | Gantt charts, progress bars, color-coded dashboards, 4D BIM models. | Oracle, SmartPM |

| Plain Language Updates | Avoid jargon; communicate delays and solutions clearly. | Example: “Electrical work on Level 3 was delayed three days; crews shifted to recovery time.” |

| On-Site Visibility | Use printed boards, posters, or live dashboards during site walks. | Giatec® 360 |

| Decision Support | Present options side-by-side: finish dates, costs, and trade-offs. | Planera, Procore |

| Access & Transparency | Provide read-only dashboard access for owners. | Azo Build |

| Honest Updates | Communicate delays early and include recovery plans. | CMAA |

Build Data Centers Faster with SmartRock® Long Range

Technology and the Future of Construction Scheduling

Construction schedules used to live in one planner’s office, now they live in the cloud, on phones, and inside smart tools that help teams stay on track. With software, sensors, and AI, construction teams can plan better, adjust faster, and avoid delays. Let’s look at how modern tech is changing the way projects stay on schedule.

Software and Collaborative Platforms

Construction scheduling has moved from static office charts to cloud-based, collaborative platforms that give teams and owners real-time visibility, help track progress, and reduce delays.

| Feature | Description | Key Benefits |

| Traditional Scheduling Tools | Time-tested software like Primavera P6 and Microsoft Project help plan complex jobs and track progress; now available in cloud versions for anytime, anywhere access. | Familiar, reliable interfaceSupports critical path schedulingRemote access for distributed teams |

| Next-Gen Platforms | Modern platforms connect schedules to drawings, documents, and field data. Teams can update progress from mobile devices and visualize work in 3D models. | Real-time field updatesMobile accessibilityVisual dashboards for performance tracking |

| Schedule Health Analysis | Uses analytics to detect logic gaps, shrinking float, or risks before they cause delays. | Early risk detectionData-driven decision-makingImproved schedule accuracy |

| Collaborative Digital Boards | Replaces sticky-note pull planning with real-time digital collaboration across trades and teams. | Enhanced coordinationTransparent task trackingFaster issue resolution |

| Dashboards & Mobile Access | Provides visual overviews of trends, completion rates, and at-risk tasks accessible from any device. | Instant visibility for teams and ownersData consistency across the projectBetter accountability |

| Connected Jobsite Integrations | Connects schedules with weather, workforce, IoT sensors, and concrete monitoring systems for automatic updates and alerts. | Real-time schedule adjustmentsFewer delays from site conditionsSmarter, data-informed management |

Modern scheduling platforms, whether traditional or next-gen, enable teams to stay aligned, respond faster to changes, and provide owners with clear, actionable insights, keeping projects on track from planning through completion.

Learn how AI and digitization are transforming construction sites in real time. Check out our Construction Revolution Podcast!

AI, Digital Twins, and Predictive Tech

Construction scheduling is moving fast into a smarter, more connected future. Tools like artificial intelligence (AI), digital twins, and predictive models are starting to change how teams plan, monitor, and fix schedules. These are not just ideas for tomorrow; many are already being tested on jobsites today.

1. AI Assistants for Schedule Creation

- AI systems, including large language models (LLMs), can automatically generate construction schedules from project plans.

- Example: CONSTRUCTA improved schedule logic by 79% compared to traditional methods.

- Soon, creating a draft schedule could be as simple as typing or speaking a command.

2. Self-Updating Schedules

- AI can adjust timelines automatically when conditions change, such as weather delays or equipment issues.

- Teams get immediate updates instead of waiting for weekly progress meetings.

3. Real-Time Inputs from Sensors & Robots

- Tools like Giatec SmartRock provide live data on concrete strength.

- Robots performing layout or inspections can feed data directly to the schedule, allowing instant adjustments.

4. Digital Twins for Scenario Planning

- 4D BIM digital twins update in real time, showing current progress and upcoming tasks.

- Teams can simulate “what-if” scenarios, such as adding crews or rescheduling deliveries, to find the most efficient path forward.

5. AI for Crew and Equipment Optimization

- AI can sequence tasks, allocate equipment, and suggest cost-effective schedule adjustments.

- Helps prevent bottlenecks and ensures crews work efficiently.

6. Real-Time Risk Alerts

- AI can assign risk scores to tasks, flag potential delays, and suggest corrective actions.

- Keeps projects on track and provides owners with early visibility.

7. Smart Links Between Schedules and Documents

- AI can cross-check contracts, specs, and RFIs against the schedule to prevent conflicts or compliance issues.

8. Company-Wide Scheduling Insights

- Large firms can use AI to monitor multiple projects simultaneously, detect recurring delays, and make better resource allocation decisions.

9. Future Outlook (3–5 Years)

- AI assistants, digital twins, and LLM-powered chat tools will become increasingly integrated into scheduling platforms.

- Teams may soon interact with schedules via natural language commands, with live jobsite data automatically updating timelines.

Conclusion

Construction scheduling has evolved from static Gantt charts to dynamic, tech-driven tools. By focusing on owner priorities, leveraging real-time monitoring, AI, and digital twins, teams can finish projects on time, reduce risk, and maintain high-quality standards. Smart scheduling isn’t just about tracking tasks; it’s about enabling better decisions, optimizing concrete quality, and building trust with own.

Want to streamline construction documentation and keep your projects on track? Check out our Construction Documentation Management Tip Sheet!