Accurately assessing concrete strength is vital for the integrity and safety of structures. There are various methods useful for concrete strength evaluation at different stages and under different conditions. Some of the most common tests are Maturity, Drilled Cores, Field-Cured Cylinders, and Lab-Cured Cylinders. In this blog, we dive into these testing methods and explore if they are comparable in terms of strength evaluation. This comprehensive comparison aims to provide engineers and construction professionals with valuable insights to make informed decisions regarding concrete testing methodologies.

Exploring Methods for Concrete Strength Evaluation

The selection of the testing method depends on several factors. This includes: project requirements, timeline constraints, cost considerations, and the type of structure being tested. In the following sections, let’s split and compare the methods based on their applicability at different construction stages. These are: Early stage (up to 14 days), mid-stage (15-27 days), and late stage (28 days and after).

Early Stage (Up to 14 days)

Typically, the early stage of construction is when concrete strength evaluation is essential for decision-making for critical operations to be performed. For example, removing formwork, applying loads, or opening roads. At this stage, the maturity method, field-cured cylinders, and lab-cured cylinders can be implemented to gauge understanding of the strength development of the structure we are building.

Field-Cured Samples

Field-cured samples are the most common method in the industry. The samples are cast and cured under real construction conditions alongside the structural elements. They will undergo tests for compressive strength at each specified age, assessments for whether the concrete is meeting the requirements, and the identification of any potential issues.

Lab-Cured Samples

In contrast, lab-cured samples are cast at the job site, but cured in controlled laboratory environments. This method offers precise control over curing conditions, ensuring consistent and reliable strength results. The sample is commonly used for quality control purposes and is usually taken for a 7-day evaluation test as outlined by ACI 318.

The Maturity Method

The maturity method is a non-destructive method. It provides a unique advantage by allowing for early-age strength results without having to wait for the specimens to be tested. Maturity is based on the concrete’s temperature history and correlation with strength development to estimate the in-place strength of the structure.

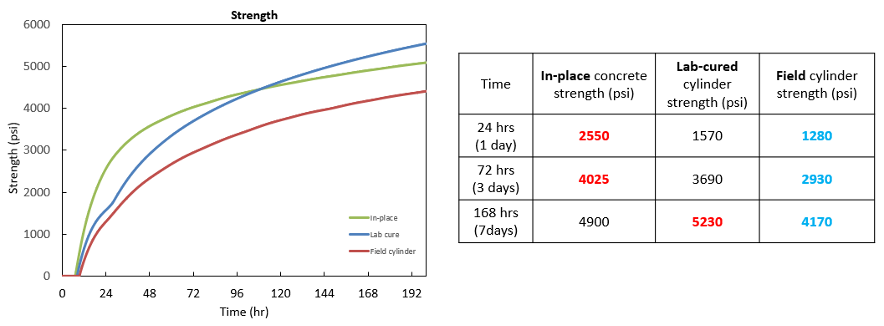

In most cases, the early-age strength of the concrete is underestimated when using the compression test for lab-cured and field-cured samples. In general, the samples have a much smaller mass and a larger surface area than the structures. This means that the heat within the samples dissipates faster. As a result, this slows down the strength gain compared to the in-place concrete. Below you can find a comparison of the strength results obtained with in-place, lab-cured, and field-cured samples.

Mid-Stage (15 to 27 days)

Given that most critical operations occur during the early stage, the mid-stage of concrete construction and strength development is very similar. It follows the procedure by accommodating the maturity method, field-cured cylinders, and lab-cured cylinders. These methods continue to be valuable in predicting strength progression. Maturity, most precisely, offers real-time in-situ monitoring, while field-cured and lab-cured serve as practical on-site indicators and quality control tools.

Late-Stage (28-days and after)

During the late stage of concrete, at the 28-day acceptance period, it is crucial to ensure the structural integrity and long-term performance of the concrete. At this stage, lab-cured samples play significant roles in acceptance testing, quality assurance, and quality control.

By testing these samples at the 28-day acceptance age, engineers can assess the concrete’s ongoing compliance with specified strength requirements.

Lab-Cured Samples

Lab-cured samples are known to be the way to ensure that the concrete requested, is what was delivered. For instance, one can assume that concrete yields a low result during winter times. But this is not because the poured concrete was not the correct mix. On the contrary, the reason concrete can have low results on site is due to site and/or environmental conditions. Thus, having a standardized method with controlled curing conditions ensures the same baseline for the samples. It also verifies if the delivered concrete meets the acceptance criteria.

It is also notable that at this stage, the extraction of samples is carried out when there are uncertainties regarding the strength and performance of the poured concrete. This uncertainty may arise due to laboratory test results falling below the expected values during the quality control phase or due to indications of concrete deterioration.

Drilling Cores

Typically, drilling cores occurs when there is non-conformity with the concrete design requirements. Specifically, when the estimated concrete strength is lower than the required strength as specified in ACI 214. Identifying this discrepancy is possible by obtaining the results from compressive strength tests on lab specimens. Depending on the results obtained on the tests performed and in-situ readings, drilled cores can also be used during early and mid-stage.

An example of mid-stage coring is when early breaks of lab samples (i.e., 7 days) are far too low and would not generate the full design strength by 28 days. In such cases, it is possible to break a 28-day sample in advance to confirm the results before deciding on coring. Alternatively, a comparative rebound hammer test can be carried out between concrete elements with no known issues and the elements with concrete being questioned.

Combining Methods for Concrete Strength Evaluation

Using various methods together can provide a more comprehensive concrete strength evaluation at different ages and conditions. Each method has its advantages and limitations, making them suitable for specific applications. Thus, one should not compare maturity readings at later ages to the results acquired by the drilled cores. This is because the maturity intent of use is for early ages. By combining methods, engineers can gain a more thorough understanding of the concrete’s strength development throughout the project timeline.

For example, the maturity method can be used during the early ages to monitor the strength. It can guide critical operations, which can be supported by field-cured cylinders. At the acceptance age of 28 days, the lab-cured cylinders should be tested for compressive strength quality control. As the project progresses, all 3 methods continue to be important and used in parallel to address the strength development. Depending on the results shown by these methods, drilled cores can be extracted at designated ages. For example, post-28 days for acceptance testing and to validate the designed/required strengths.

Assessment Methods Ensure Safe Structures

In conclusion, accurately assessing concrete strength is vital for ensuring the integrity and safety of structures. By comparing the concrete strength evaluation methods—maturity, drilled cores, field-cured cylinders, and lab-cured cylinders—we gain valuable insights into their applicability at different stages of construction. Proper coordination, planning, and interpretation of the results are necessary when using all the methods together. Understanding the strengths and limitations of each method is crucial to ensure an accurate and reliable assessment of concrete strength throughout the project lifecycle.