How many times have you heard people use the words cement and concrete interchangeably? Probably enough for you to wonder if there is a difference at all. While there are some ways in which the terms are related, the answer is simple: concrete and cement are fundamentally different. In this blog, we will discuss all you need to know to answer the question: cement vs concrete, are they different?

What Is Cement?

Cement, as explained in Cement Chemistry, is a mixture that typically comes from limestone and clay. Sometimes, it can also have materials that are similar in their bulk composition. After these materials have been obtained through mining, they undergo a 1450°C heating process. This is when the materials are crushed and combined producing lumps of clinker. Manufacturers add other minerals such as calcium sulfate and sometimes aluminum and iron. Later, this mixture goes through a grinding process that will turn it into the fine powder we know as cement. In the construction industry, Portland is the most common type of cement. Portland is not a brand name, but rather a generic term that helps differentiate the different kinds of cement in the market. Portland cement is hydraulic, which means that it has a chemical binding reaction with water.

What Is Concrete?

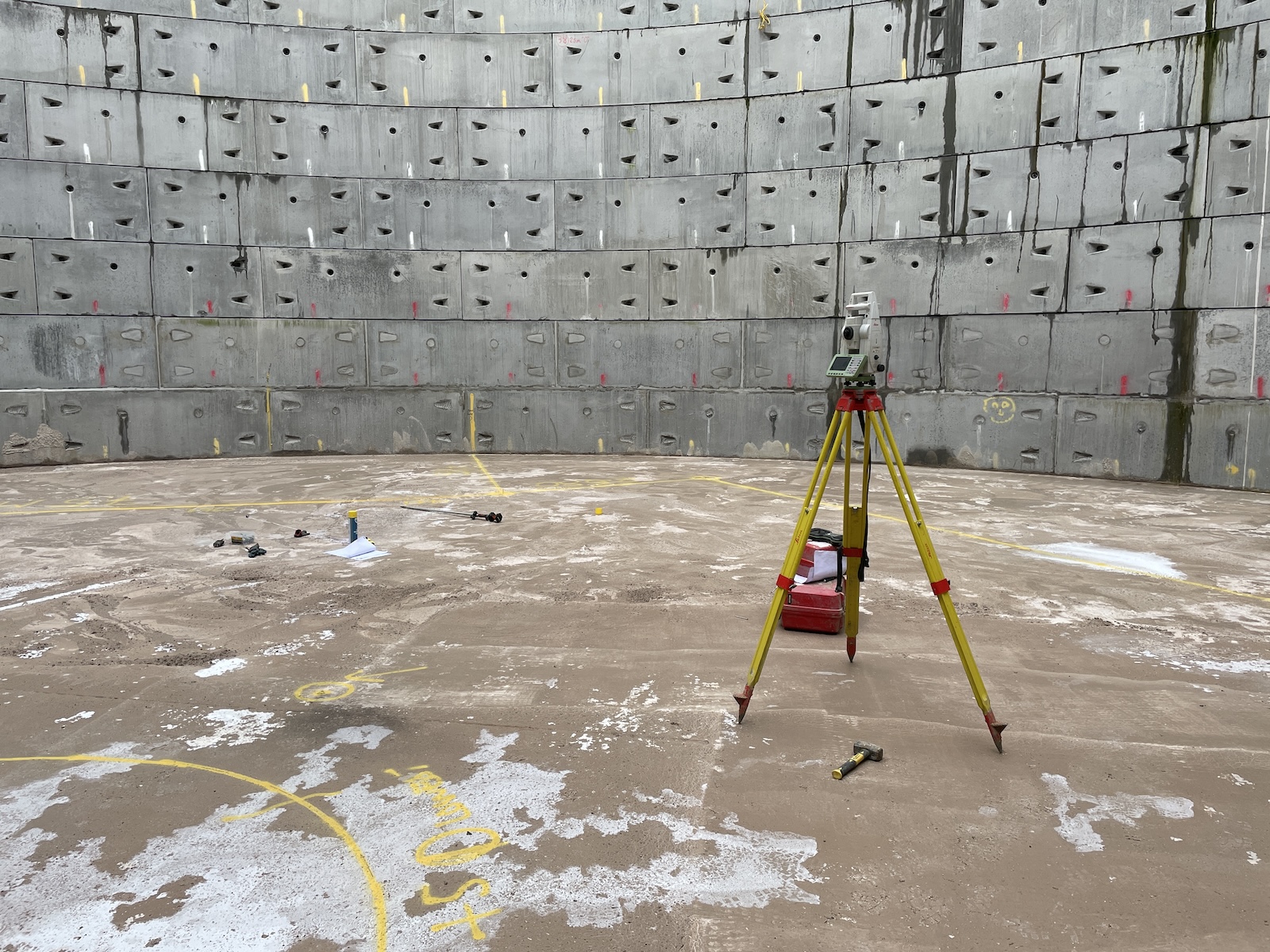

On the other hand, concrete is a building material that uses cement as one of its components. It is often a top-choice material because it is extremely durable. Apart from being able to resist harsh environments, concrete is versatile because it adapts to the specifics of the project needs. This durable mixture is a combination of paste and aggregates. The American Concrete Institute indicates that the usual composition is “cement, aggregates, and water, with or without admixtures, fibers, or other cementitious materials.” Perhaps the most common way to make concrete is the ready-mix form. This is a high-quality type of concrete that is mass-produced and made to be delivered directly to the jobsite.

Learn all you need to know about concrete (not cement!) monitoring

How Are They Related?

Cement is an important part of concrete because it acts as the paste of the mixture. In a chemical reaction called hydration, water helps hydraulic cement adhere to other cement particles and the aggregates of the mixture. Good concrete will have the right amount of water to make sure that the hydration process creates good quality paste. The concrete will become difficult to work with if there is too little or too much water. Thus, it is important to design appropriate proportion plans depending on the type of structure that contractors desire to build.

The Benefits of Using Concrete

Concrete is a very popular material in the industry. Thanks to its versatility, concrete is present in a wide range of structures like tunnels, bridges, high-rise buildings, dams, etc. Concrete can also resist very high temperatures that either come from the weather or blazing fires. Therefore, contractors often use it as a protective layer for steel structures. According to Advanced Concrete Technologies, concrete has become a sustainable material for construction given that it can consume industrial waste by replacing typical aggregates for waste glass or ground vehicle tires.

Click to learn more about how to reduce your cement usage with SmartMix™!

In short, the difference between cement vs concrete is easy to clear once we know all the basics of their compositions. Cement is a binding agent made from limestone and clay; whereas concrete is a building material created through the proper mixing of cement, water, sand, and rock. Keep learning more and review Giatec’s unique concrete knowledge resources here.