Concrete delivery is one of the most vulnerable phases of a construction project. From plant to pour, variables like time, temperature, and agitation affect fresh concrete quality. Manual slump tests at the jobsite remain the default for acceptance, but they are time-consuming, often inconsistent, and come too late to make proactive corrections.

Want to take the guesswork out of concrete slump?

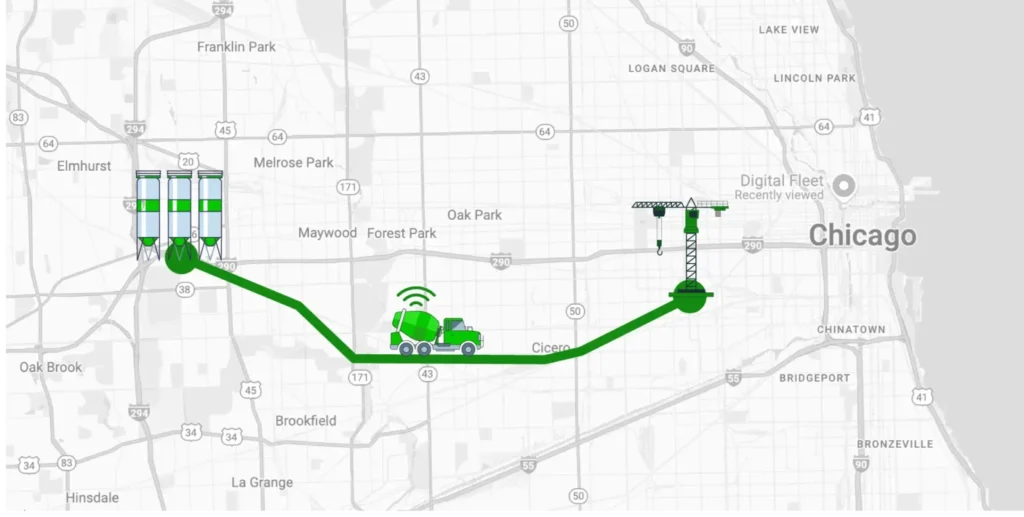

With advanced concrete systems, real-time, in-transit monitoring technologies can provide live data on slump, temperature, and volume. Before the truck reaches the jobsite, allowing them to reduce potential rejections and simplify documentation. As digital ticketing and performance-based specifications become more common, these tools are transforming how quality control is managed across the concrete supply chain.

In this blog, let’s compare the latest advanced concrete systems for in-transit monitoring.

Why In-Transit Monitoring Matters

Producers are under increasing pressure to deliver consistent, compliant concrete with fewer callbacks and better concrete performance traceability at the load-level to support post-pour review and dispute resolution. Truck-mounted sensors provide critical real-time data during transport, including slump/workability, temperature, drum behavior, and water additions.

This information helps crews pour on time, stay within specifications, and avoid costly delays or rework. With many DOTs adopting digital workflows and e-Ticketing, in-transit data, such as statuses, slump, temperature, batching, pouring times, and everything in between, is becoming essential for internal quality control and verifiable, load-specific performance records in the field.

How Does In-Transit Real-Time Monitoring Work?

In-transit monitoring systems use a combination of sensors and onboard computing to analyze the physical behavior of concrete inside the mixer. Key data points include:

- Drum rotation speed and direction

- Internal pressure and torque

- Water added versus allowed

- Estimated concrete volume

These indicators are processed to calculate fresh concrete properties. Some systems offer AI or algorithmic enhancement to improve accuracy and require calibration and periodic adjustments to ensure data reliability. The resulting data is typically transmitted via cellular or satellite connection to cloud-based dashboards, enabling real-time visibility at the plant, in the field, or at headquarters.

What are the Standards, Accuracy, and Compliance for In-Transit Monitoring?

While in-transit data is valuable for quality control, regulatory acceptance remains limited. Here’s what you need to know:

- ASTM C94 governs delivery time and documentation, including rules for water addition and the 30-revolution after water is added requirement

- ASTM C143 (slump) and ASTM C1064 (temperature) are still the baseline for field acceptance

- AASHTO 2025 standards support performance-based methods like ASTM C1074 (maturity), but DOT adoption varies widely

In most jurisdictions, in-truck data is for internal QC only unless specified otherwise in pilot programs or special provisions.

Types of In-Transit Concrete Monitoring Methods

In-transit concrete monitoring methods can be categorized based on different aspects of quality control, automation, and fleet management. Understanding these types helps producers choose solutions that fit their operational needs and compliance requirements.

1. ASTM C143

The manual slump test remains the industry standard for concrete acceptance. While in-transit systems provide valuable real-time data, they currently serve to supplement manual field testing in most jurisdictions, not to replace. The slump test is quick and simple, but it can be inconsistent, particularly with stiff or fluid mixes. It is also affected by aggregate size and can be prone to human error due to technique. As a general indicator of workability, ASTM C143 provides useful guidance, but it may not fully reflect the concrete quality requirements or placement conditions specific to a given application.

2. Slump, Temperature, and Volume Monitoring Systems

These systems measure key properties of fresh concrete—slump (workability), temperature, and volume—while the mix is moving. They provide real-time data to cloud platforms. This allows producers to track consistency and catch potential issues before delivery. While they do not automate dosing, they often provide useful guidance for making adjustments in transit.

3. Automated Dosing and Rheology Control Systems

These platforms build on basic monitoring capabilities by adding closed-loop control of water and admixtures during transit. They use real-time sensor data to keep slump and other properties within set limits, which are designed to meet with standards like ASTM C94. These systems often integrate with batch plant automation and dispatch tools, offering automated quality control throughout the delivery cycle.

4. Air Content and Temperature Monitoring Systems

These systems focus on monitoring air content and temperature during delivery, which is essential for projects that have durability or cold-weather needs. They do not support dosing in transit, but they provide somewhat accurate validation of air properties when used with compatible drum setups and proper calibration.

5. Fleet Telematics and Operational Tracking Platforms

These platforms concentrate on logistics instead of material quality. They offer insights into delivery operations, such as drum rotation, GPS tracking, driver behavior, truck status (e.g., loading, enroute, pouring), and water additions. They help improve scheduling, maintenance, and dispatch decisions, but usually lack advanced features for controlling mix properties or automated dosing.

Advanced In-Transit Concrete Systems and Technologies In the Market

The landscape of concrete monitoring during transit includes various systems, each providing different levels of automation, data visibility, and integration. These systems are designed to meet the changing quality control needs of producers and contractors.

Let’s take a look at in-transit concrete monitoring solutions available on the market.

Verifi by Saint-Gobain (Chryso)

A full-featured in-transit monitoring and control system capable of automatically dosing water and admixtures within preset limits. It supports ASTM C94 requirements for in-transit adjustments, offering closed-loop control that supports field compliance. Verifi is suited for large producers with extensive fleets.

Load Assurance by Command Alkon

Captures a range of data, including slump, air content, temperature, drum rotations, and volume. This system is ideal for producers already using Command’s software stack who want to expand QC visibility across the fleet.

CiDRA SMARThatch / AIRtrac

Specializes in measuring air content and temperature during delivery. These tools are validated for specific mixes and require compatible drum configurations to ensure accurate results. They are particularly useful in cold climates or on projects where air content control is critical for durability.

Digital Fleet+ by Command Alkon

Provides visibility into truck statuses, water additions, driver logs, and drum behavior, with limited and indirect insight into slump metrics. It is telematics-focused and designed primarily for operational tracking rather than spec-based control, with slump gauged through pressure readings. This makes it a good fit for fleets prioritizing logistics and maintenance over advanced quality monitoring.

MixPilot™ by Giatec

A robust, self-calibrating, non-invasive solution that ensures accurate, real-time monitoring from plant to pour. MixPilot uses a wireless hydraulic pressure sensor along with a unique magnetic drum sensor to reliably measure key concrete metrics. This provides real-time data on slump, temperature, drum rotations, statuses, return volume and water added, making it useful for producers who need quick deployment and effective monitoring across large fleets.

How can you optimize your concrete from fleet to finish? Listen to our podcast to learn more.

Which Advanced Concrete In-Transit Monitoring System Should You Choose?

Choosing the right in-transit monitoring system depends on your operational goals, project types, and tech stack. Some solutions offer full automation and dosing control. Others focus on visibility and ease of integration.

The table below compares key players based on functionality, connectivity, and ideal fit. This will help you identify which system is the best match for your production and quality control needs.

| System | Measurements | In-Transit Dosing | Cloud/API | Primary Value | Ideal Fit |

| ASTM C143 | Manual slump test | No | N/A | Field acceptance standard | All spec-compliant projects |

| Verifi | Slump, temperature, volume | Automated | Yes | ASTM C94-compliant auto-dosing | Producers looking to dose concrete during production or delivery |

| Load Assurance | Slump, temperature, air, water, volume | Visibility only | Yes | Detailed QC insights via Command Cloud | Command Alkon users |

| CiDRA AIRtrac | Air content, temperature | No | Yes | Validated air control for select mixes and drums | Air-critical projects; cold climates |

| Digital Fleet+ | Slump meter, water additions, drum metrics | No | Yes | Operational visibility; telematics-focused | Telematics-driven operations |

| MixPilot | Slump, temperature, volume | Guidance only | Yes | Non-invasive | Ready-mix producers of all sizes |

With more options than ever, the best in-transit monitoring system is the one that fits your unique mix designs, fleet setup, and quality control goals. Each solution has different strengths, ranging from AI-based optimization to durable, telematics-ready setups. As job site expectations grow, investing in the right system now lays the groundwork for smarter and more efficient concrete delivery in the future.

Ideal Use Cases for In-Transit Monitoring

The value of real-time concrete data varies based on the specific use case, from high-output paving operations to remote infrastructure work. Below are common scenarios where these systems provide the greatest return.

- High-volume paving and flatwork: Reduces variability and accelerates placements

- Urban job sites: Supports narrow pour windows and tight logistics

- DOT and infrastructure work: Enhances traceability and supports digital audits

- Cold-weather and air-sensitive mixes: Monitors critical parameters in transit

- Remote or hard-to-access projects: Provides QC visibility where field testing is impractical

- Mixed truck fleets: Ensures consistent monitoring across front/rear discharge models

- Sustainability-driven operations: Helps reduce material waste, optimize water use, and support CO₂ reduction targets through better in-transit control

By matching system capabilities with specific project needs, producers can get the most from their investment in in-transit monitoring. Pairing these advanced concrete systems with the right projects offers more confidence and control for every delivery.

Want to take the guesswork out of concrete slump?

Integration, Compatibility, and Deployment

A future-ready monitoring system should include:

- Reliable hardware with near-continuous uptime across regions, requiring minimal maintenance

- A resilient system capable of withstanding harsh concrete environments and operating conditions

- Secure cloud access with role-based permissions

- Open APIs for batch plant, dispatch, and e-Ticketing integration

- Refresh rates suitable for real-time adjustments

- Minimal calibration and non-invasive installation

These advanced concrete systems are designed for easy rollout, making them well-suited for producers who want to scale their digital QC programs without costly retrofits.

Automation at Scale: Labor Efficiency and ROI

Many in-transit monitoring systems introduce operational tradeoffs alongside their benefits. Common challenges include:

- Intrusive or complex hardware that increases installation and maintenance effort

- Frequent calibration or mix-dependent tuning, limiting reliability across applications

- Inconsistent uptime, reducing confidence in day-to-day use

- Ongoing reliance on manual testing and senior QC judgment, despite added technology

Systems designed to overcome these limitations, like MixPilot, use reliable, low-maintenance automation and continuous plant-to-pour visibility to reduce manual intervention, on-site adjustments, and corrective actions. Producers adopting these approaches typically see fewer rejected loads, shorter cycle times, and improved truck utilization, where even small-time savings can translate into ROI at operating costs of roughly $2 per minute per truck.

As labor constraints intensify and driver turnover remains high, automation helps standardize performance across fleets by embedding consistency into everyday operations. Reducing dependence on senior QC personnel shortens training cycles, enables fewer staff to manage more loads, and supports stronger margins and long-term operational resilience.

But How Can MixPilot Save on Costs?

MixPilot helps reduce operating costs by minimizing rejected loads, shortening delivery cycle times, and reducing manual adjustments in the field. By improving in-transit consistency and automating quality visibility, even small savings per truck translate into meaningful daily and annual cost reductions across the fleet.

To illustrate this impact, let’s take a look at an example!

A MixPilot ROI Scenario

Even for well-run producers, avoidable costs can accumulate quickly, especially when quality issues aren’t detected early enough or when variability forces crews to troubleshoot in the field. Let’s say you’re a concrete producer with a fleet size of 75 trucks and your annual production volume of around 125k m³.

There are three major areas that can cause annual losses. In this scenario, these estimates represent your potential costs:

- Rejected or reworked loads: The estimated annual impact ~$75k to $100k

- Jobsite rework and last-minute adjustments due to limited in-transit visibility: The estimated annual impact ~$3K–$10K

- Driver onboarding and ramp-up efficiency: The estimated annual impact $120k – $150k

Together, these can represent a mid-to-high six-figure annual cost burden that is often hidden across daily operations.

By providing real-time visibility into concrete performance while trucks are in transit, MixPilot helps detect issues earlier, reduce variability at the jobsite, and embed best practices directly in the cab.

For fleets of this size, MixPilot typically enables:

- ~$3K–$5K in recovered value per truck per year

- 20–40% fewer rejected or reworked loads

- 10–30% reduction in jobsite rework and adjustments

- 20–40% faster driver time-to-productivity

At scale, these improvements can translate into high six-figure annual savings, with impact increasing as fleet size and production volume grow.

| Parameter | Example Value |

| Annual Production Volume | ~125k m³ |

| Fleet Size | ~75 trucks |

| Avoidable Quality-Related Losses | ~$180k-$260k |

| Typical MixPilot Recovery | Majority of avoidable losses |

| Estimated Annual Impact | High six-figure range |

Disclaimer: This example is provided for illustrative purposes only and is based on generalized assumptions. Actual results will vary depending on fleet operations, mix designs, site conditions, and quality practices. Figures shown represent estimated ranges, not guaranteed outcomes.

Solving Common Delivery Challenges with In-Transit Slump Monitoring

MixPilot helps producers turn in-transit quality monitoring into measurable operational savings by addressing common delivery pain points, including quality issues identified too late, trial-and-error adjustments at the pour, and longer learning curves for new drivers:

- Confidence at delivery: Continuous in-transit slump monitoring helps producers and drivers verify concrete performance, even with traffic delays, temperature fluctuations due to variable weather conditions, or jobsite setbacks.

- Fewer last-minute adjustments: Real-time slump/workability visibility reduces trial-and-error water additions and re-adjustments at the pour, saving minutes on affected loads and keeping crews on schedule.

- Lower operational waste: By catching problems earlier and supporting corrective action in transit, MixPilot helps prevent rejected loads, rework, returns, and back-and-forth trips to the plant, avoiding added time on the road, higher labor costs, and dispatch disruption.

- More consistent fleet performance: Embedded best practices help new drivers build confidence faster and reduce reliance on experienced QC personnel, minimizing early mistakes and the need for frequent intervention.

- Stronger ROI over time: Fewer delays, fewer returns, and shorter driver learning curves translate into recovered productivity and real cost savings across the fleet.

As shown in the example above, the estimated savings are driven by scale, highlighting how incremental improvements can accumulate. To see how MixPilot can impact your ROI, Giatec has created a free calculator for you! You will only need to input your fleet size and annual production volume.

See how MixPilot can transform your ready-mix operations’ ROI. Check out our MixPilot ROI Calculator!

Conclusion

The construction industry is at a turning point. Performance-based specifications, digital reporting, and e-Ticketing are becoming more common. In-transit monitoring is now essential, forming the basis of a modern, transparent quality control system.

Even though many areas still limit the use of sensor data, its benefits are obvious. Producers looking for non-invasive, scalable solutions that lower risk and support digital change find MixPilot to be a reliable option for complete visibility from plant to pour. It’s time to transform your concrete operations with an advanced concrete system designed for today’s jobsite needs.

Learn how the industry’s leading concrete producers found immediate value with MixPilot. Read our Case Study!

Note: All company, product/service names, and brands used in this article are property of their respective owners. This article is intended to be used for informational purposes only.