In the world of concrete technology, achieving optimal performance is crucial. However, special precautions must be taken to comply with standards and have the best-finalized element. One of the critical documents that guide construction professionals in achieving these goals is ACI 207. It provides valuable insights into temperature control and best practices for Mass Concrete. In this blog, we will dive into how construction professionals can make use of the Performance-Based Temperature Difference Limit (PBTDL) outlined in ACI 207 and leverage the maturity method to optimize their concrete construction projects.

ACI 207: An Overview

The American Concrete Institute (ACI) publishes numerous documents and guidelines for construction professionals. ACI 207 is one such document that focuses on mass concrete, particularly in structures where temperature differentials can significantly impact performance and durability.

Understanding Performance-Based Temperature Difference Limit (PBTDL) and its Significance

One of the key aspects of ACI 207 is the introduction of the Performance-Based Temperature Difference Limit (PBTDL) to avoid either internal or external restraint. This concept is based on the thermal stress development of a concrete element. This means that if the surface cools too quickly, it can result in the development of tensile stresses. Ultimately, this leads to thermal cracking. To prevent these stresses, it is prudent to do the following:

- Set a maximum permissible temperature differential during curing.

- Promote a more balanced cooling rate of the concrete element.

- Ensure that the temperature disparity within the element does not induce tensile stress exceeding the concrete’s strength.

The PBTDL replaces the traditional fixed temperature differential limits and allows construction professionals to tailor their concrete mix designs and construction practices to specific project requirements.

DOT Acceptance and Compliance

As state DOTs across the US place great emphasis on ACI, understanding and implementing PBTDL not only ensures adherence to industry best practices but also facilitates smoother acceptance and quality processes. This compliance can make a significant difference in the speed and efficiency of project approvals, particularly for contractors working across multiple states.

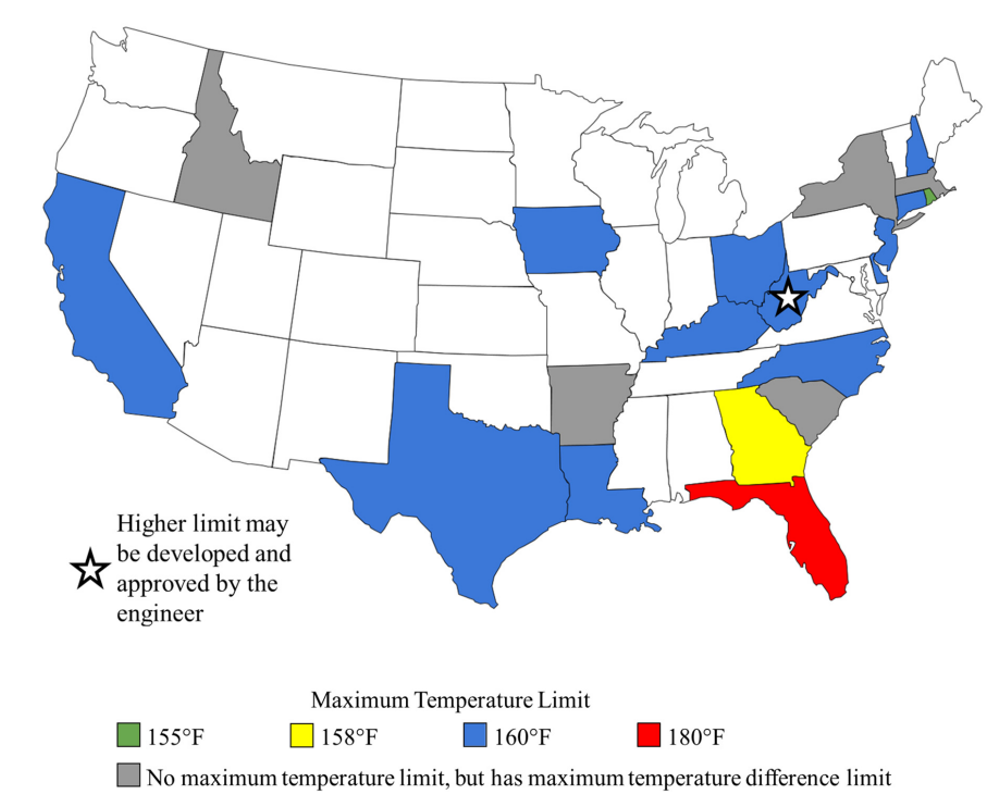

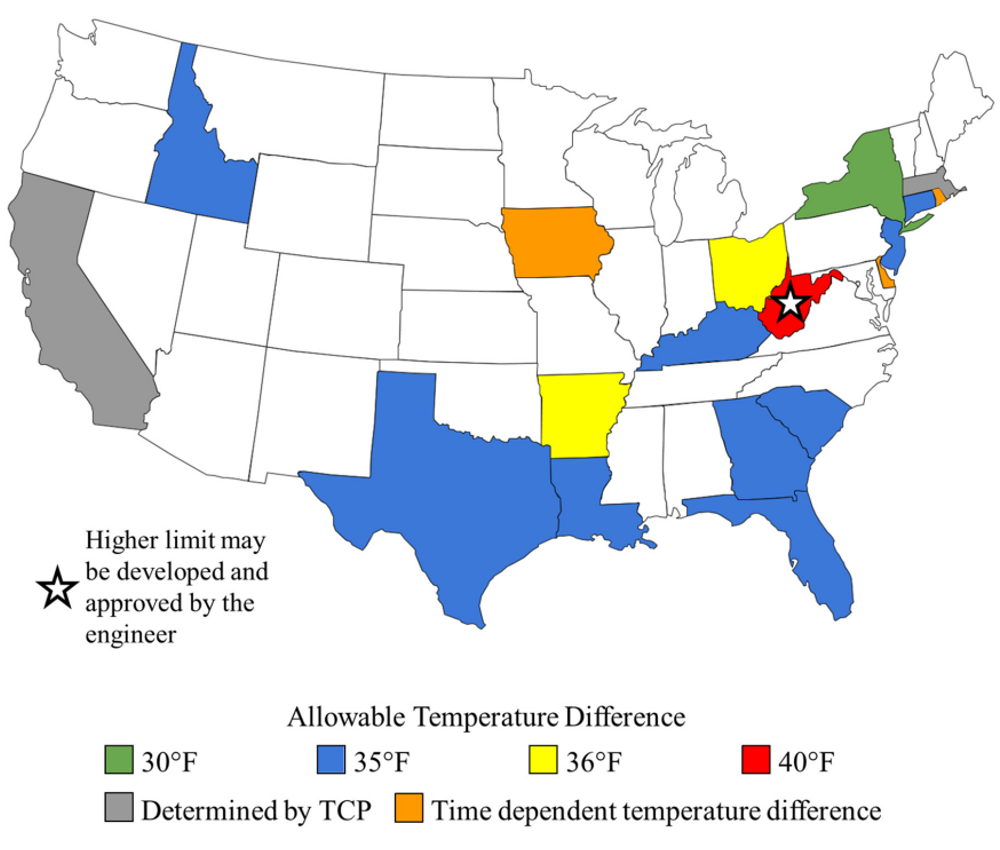

Currently, most states specify a maximum concrete temperature at placement, maximum in-place concrete temperature, and fixed maximum temperature difference, which does not consider the performance/maturity of concrete as a variable to the temperature difference limit. The use of temperature prediction models and thermal control plans enables the development of performance-based specifications to avoid the short service life of concrete.

The images above describe what has been mentioned, so far only the temperature differential requirements outlined by Delaware, Iowa, and Rhode Island integrate a parameter of time for concrete temperature difference, factoring in the escalating tensile strength of maturing concrete, enabling it to endure higher levels of temperature-induced stress. Although similar, this parameter does not consider the performance of concrete, including the maturity index.

Leveraging Maturity for Greater Flexibility

As the Maturity Method is a temperature-time factor with a correlation to in-place strength development, contractors frequently employ it in conjunction with a Performance-Based Temperature Differential Limit to expedite construction schedules and allow greater flexibility. Also, if Supplementary Cementing Materials and specific admixtures are used in the mix’s constituents the PBTDL will take into consideration the different hydration patterns and heat gain given by these SCMs. By closely tracking the development of concrete strength in real-time, contractors gain a comprehensive understanding of the mix behavior.

It is important to note that PBTDL is not a static value. As time progresses and there is strength development, the allowable temperature differential can increase. This dynamic aspect of the standard affords contractors the opportunity to plan and execute their projects with a nuanced understanding of how temperature differentials will evolve over time, empowering contractors to adapt their construction schedule to capitalize on these evolving limits.

The Synergy of Maturity and PBTDL

Construction professionals can effectively utilize the Performance-Based Temperature Difference Limit (PBTDL) in a structured approach. Initially, a comprehensive risk assessment is imperative, focusing on temperature differentials specific to the concrete project. Factors such as climate conditions, structural dimensions, and geometry must be carefully considered, as they significantly influence the permissible temperature differentials.

Collaboration with concrete suppliers becomes pivotal in this process. Together, they delve into the nuances of cement types, admixtures, and aggregates to craft a concrete mix design that can withstand the expected temperature fluctuations. This phase lays the foundation for success, ensuring that the concrete will perform optimally under the anticipated conditions.

A continuous monitoring and control regime over concrete temperatures during both the placement and curing stages is essential. This rigorous oversight guarantees that the temperatures consistently adhere to the prescribed limits, thereby upholding the integrity and quality of the concrete.

Furthermore, this approach has a positive environmental impact. Optimized concrete mix designs and construction practices contribute to reduced material waste and energy consumption. One significant aspect to highlight is the impact on cement content, a crucial factor in the ecological footprint of concrete production.

Through optimization, mixes can be formulated with lower cement content, thereby lessening the strain on environmental resources. This reduction in cement usage not only enhances the sustainability of the project but also underscores a conscientious approach, ultimately benefiting both the project and the wider ecosystem.

Conclusion: Elevating Concrete Performance

In conclusion, the use of ACI 207, Performance Based Temperature Differential Limit, and maturity methods represent a paradigm shift in the world of concrete construction. Understanding and implementing these can elevate project outcomes to new heights.

From ensuring structural integrity to expediting DOT acceptance, these practices have a far-reaching impact on the industry. The dynamic nature of PBTDL, combined with the power of the maturity method, provides a level of precision and flexibility previously unseen in concrete construction.

By embracing these principles, construction professionals can navigate the complexities of diverse projects with confidence. The result is not only superior concrete performance but also a more efficient, cost-effective, and sustainable approach to construction.

References

- Gross, Eric D; Eiland, Andrew D; Schindler, Anton K.; Barnes, Robert W. “Temperature Control Requirements for the Construction of Mass Concrete Members”. Auburn University/Highway Research Center, 930-860R, 2017. https://rosap.ntl.bts.gov/view/dot/42366

- ACI 207. 2005. Guide to Mass Concrete. American Concrete Institute. Farmington Hills, MI.

- ACI 207. 2005. Cooling and Insulating Systems for Mass Concrete. American Concrete Institute. Farmington Hills, MI.

- ACI 207. 2007. Report on Thermal and Volume Change Effects on Cracking of Mass Concrete. American Concrete Institute. Farmington Hills, MI.