In January 2025, Giatec launched MixPilot, a groundbreaking slump sensor that’s set to revolutionize how concrete producers manage quality in transit. MixPilot is a fully non-invasive and self-calibrating sensor, allowing users to install in just 15 minutes. It provides real-time insights into concrete slump, temperature, and volume.

To ensure MixPilot delivers maximum value, Giatec conducted an Early Adopter (EA) program with five leading producers across North America. The program provided invaluable feedback, helping shape MixPilot into a powerful tool for producers looking to optimize their in-transit quality control.

Testing Under Real-World Conditions

The five customers that participated in the program were Tomlinson Ready-Mix, BARD Materials, MMC Materials, Irving Materials, and Maschmeyer Concrete. These companies, with varying fleet configurations and operational software systems provided diverse use cases to test MixPilot’s scalability.

To ensure the technology could deliver real-world value across a range of operations, the program focused on three key goals:

- Proving the accuracy of the slump measurements.

- Validating the durability of the hardware.

- Identifying necessary integrations and data flow for decision making.

As part of the program, all participants met at BARD Materials’ headquarters in Dubuque, Iowa. A key aspect of the visit was to prove the hardware’s durability and performance in day-to-day concrete operations. MixPilot’s sleek design and simple hardware initially raised doubts about its durability. However, testing confirmed the hardware’s robustness in real-world conditions, clearing any doubts.

Key Findings from the EA Program

The EA program provided valuable insights into MixPilot’s operational performance and highlighted areas for further improvement. Key findings included:

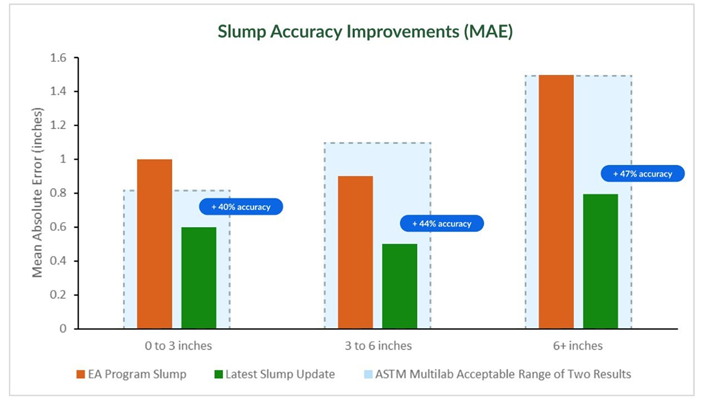

- Significant Accuracy Improvements: Prior to the program, slump readings often fell outside the ASTM acceptable range of two slump test results due to high variability. After algorithm adjustments driven by producer data, accuracy improved significantly, consistently producing results within the ASTM acceptable range of two slump test results.

- Proven Market Demand: The early adopters’ feedback led to rapid improvements, allowing Giatec to secure full fleet commitments and sell out even before the official launch.

- Installation Best Practices: No challenges were linked to the sensors. The only variability arose from installation practices, which was quickly resolved with clear instructions.

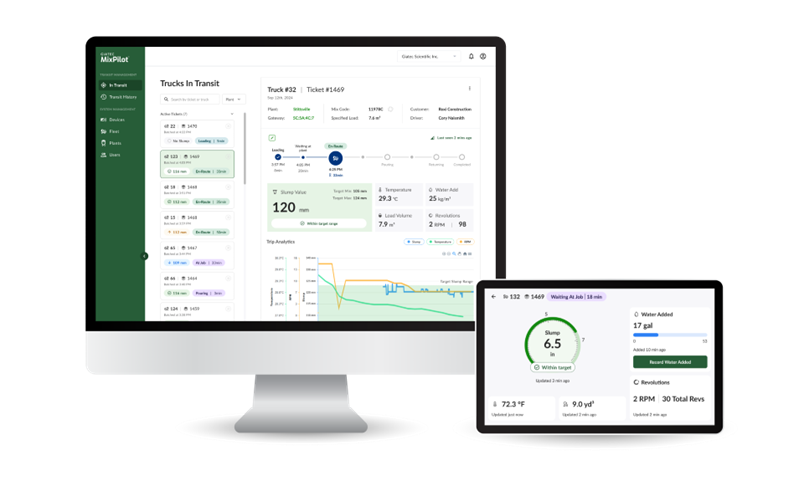

- Enhanced Data Visibility: The web dashboard and in-cab display were quickly developed based on user feedback, providing easy access to real-time data.

- Future Enhancements: Ongoing updates will further enhance functionality and user experience, empowering all users to get the most out of the system.

Proven Value for Concrete Producers

As the first truly reliable in-transit concrete slump sensor, MixPilot has transformed how producers manage quality from plant to pour:

- Most Accurate Slump: MixPilot delivers the most accurate real-time slump, temperature, and volume data, transforming every truck into a quality controlled load.

- Maintenance-Free System: MixPilot requires minimal maintenance, delivering consistent performance and eliminating downtime.

- Enhanced Communication: Experts across the entire concrete manufacturing ecosystem receive insights in real-time, ensuring everyone stays informed.

- Actionable Insights: MixPilot not only delivers reliable quality data, but also provides actionable insights, empowering proactive decision-making.

- Empowered Drivers: MixPilot’s in-cab display and real-time alerts empowers drivers with the insights needed to make faster, smarter decisions.

Actionable Concrete Slump Insights

One standout insight from the EA program is that MixPilot’s real-time data helps producers shift from reactive to proactive quality control. Instead of waiting for issues to arise, users can now detect potential quality deviations before they impact the job site or escalate further up the supply chain.

“We’ve already seen several opportunities where relying on MixPilot’s data could have prevented a load loss.”

Steve Bishop, President and COO, Maschmeyer Concrete

Revolutionizing In-Transit Concrete Quality Control

The EA program was instrumental in shaping MixPilot into the advanced slump monitoring system that it is today. The hands-on feedback from leading producers allowed Giatec to refine the hardware, enhance accuracy, and optimize the user experience. This ensured that MixPilot meets the real-world demands of in-transit concrete quality control. Without this program, MixPilot would not have achieved the same level of operational performance, market readiness, or industry confidence. The EA program’s insights directly contributed to a system that empowers producers with actionable insights, streamlines operations, and sets a new standard for managing concrete quality from plant to pour.