A Legacy of Quality, A Future of Innovation

With a deep-rooted legacy in the concrete industry, Modern Concrete & Materials was founded in 2019 in Southeast Texas by Trent Almond. This was over a decade after his father, Doug Almond, sold Quality Concrete & Materials, which he had established in 1997. Inspired by his family’s background and driven to build a truly modern concrete company, Trent sought to improve quality through technology.

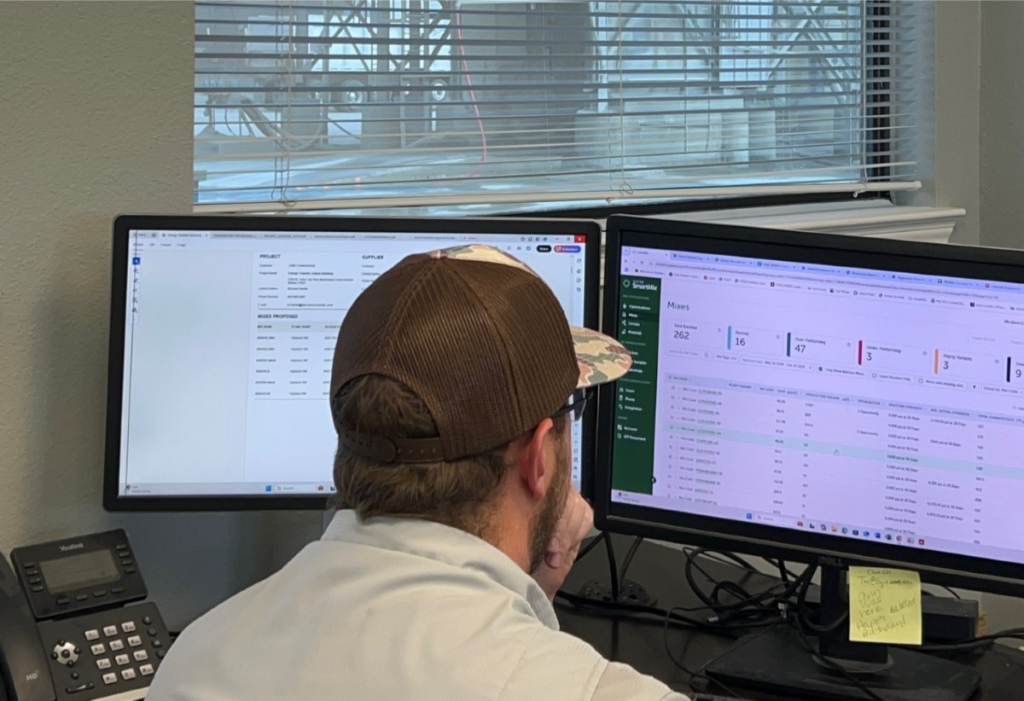

For five years, the company operated without a dedicated concrete quality control software. However, as growth accelerated, so did the need for a single source of truth for all their mix data. With data stored across multiple spreadsheets, compiling and analyzing information became a time-consuming, manual effort. While this approach worked, it made it difficult to consolidate and interpret the data efficiently. Without a centralized system, the quality control team struggled to be as proactive as they wanted, spending more time gathering data than analyzing it.

New Era in Concrete Quality Control

While they initially set out to find a simple concrete quality control solution, the team quickly recognized the potential of Giatec® SmartMix™ — an intuitive concrete quality control system designed to streamline operations and bring data into a single centralized platform. Upon exploring SmartMix’s full capabilities, they understood that investing in a more advanced software would provide far greater long-term benefits. As Trey Lambert, Quality Control Manager, said, “At first, we were just looking to organize our data better, but SmartMix takes it a step further. It brings the optimizations right to us, faster than we could do manually. The potential is huge.”

In only one month, SmartMix helped them transition from manual data entry to a fully automated system, guided by the Giatec Team’s support. Consolidating all their mix, material, and performance-related test data, SmartMix empowered the team to make faster, more strategic decisions. “It wasn’t just about having the data. It was about having it in a way that we could use efficiently,” Trey explained. The seamless integration of SmartMix into their existing workflow made the transition smooth, with minimal disruptions to their operations.

Fast-Tracked Success with SmartMix

The decision to implement SmartMix quickly paid off as Modern Concrete & Materials saw immediate improvements in efficiency. Leveraging the SmartDocs feature, SmartMix automatically uploads their third-party data and sends notifications when issues arise or new optimization opportunities appear. Prior to SmartMix, inputting data from reports would take anywhere from 4-5 days, leaving little to no time for analysis. Now, the process takes just an hour, freeing up almost an entire workweek for more strategic decision-making. Similarly, submittals that previously took 10-15 minutes each can now be generated in just a couple of minutes with a few clicks. Enabling 10x more efficiency in submittal processing, this shift freed up their time to focus on what really matters. “The workflow is what stood out the most,” Trey explained. “It’s simple, fast, and lets us focus on what really matters: optimizing our mixes.”

Beyond time savings, the AI-driven approach to mix optimization aligned with their goal to remain “modern” and stay ahead of the curve. As Trent Almond, President, shared, “AI is a game-changer for this industry and many others. We wanted to be proactive and start using it to our advantage.” The consolidation of data allowed them to identify areas for stronger resource management and waste reduction. This enabled them to monitor variability more closely and make steady, incremental changes, resulting in significant operational and qualitative savings. In addition, SmartMix has given the team the ability to proactively troubleshoot by analyzing standard deviations across various plants. This allows them to identify issues early and make adjustments before problems escalate. Furthermore, they can track mix performance over time, pulling up graphs to identify past mix revisions and determine necessary changes. This granular insight into mix performance helps to fine-tune their processes and ensure consistent quality.

Onboarding and working with the Giatec team was awesome. They were thorough, made the process seamless, and were always available to answer questions and help us unlock the full potential of SmartMix.” Trent Almond, President, Modern Concrete & Materials

Looking Ahead: A Long-Term Strategy

As Modern Concrete & Materials continues to scale, SmartMix remains a critical part of their long-term strategy. The company plans to leverage even more features to optimize operations, focusing on deeper insights into their supply chain and production efficiency. With reliable, real-time data, SmartMix will support their ongoing efforts to improve the quality and consistency of their concrete mix designs, helping maintain the high standards of service they’re known for.

While still early in their adoption, Modern Concrete & Materials has already optimized several mixes. In just the first year, they are forecasting six-figure savings and demonstrating a 300% ROI. As they continue to leverage SmartMix, they highlight the top three impacts it has had on their operations thus far:

-

- Seamless Quality Control – The most intuitive mix management platform, centralizing all concrete quality control data for easy access and troubleshooting.

-

- Instant Mix Savings – The only AI-powered platform that quantifies concrete mix savings in real-time, delivering actionable insights from the world’s largest AI concrete mixture database.

-

- Enhanced Operational Efficiency – Automated data flow and processing to streamline operations and enable teams to focus on proactive analysis in a fast-paced market.

With SmartMix, Modern Concrete & Materials is not only improving their current processes—they are laying the groundwork for a smarter, more efficient future. “It’s all about staying modern,” Trent concludes.