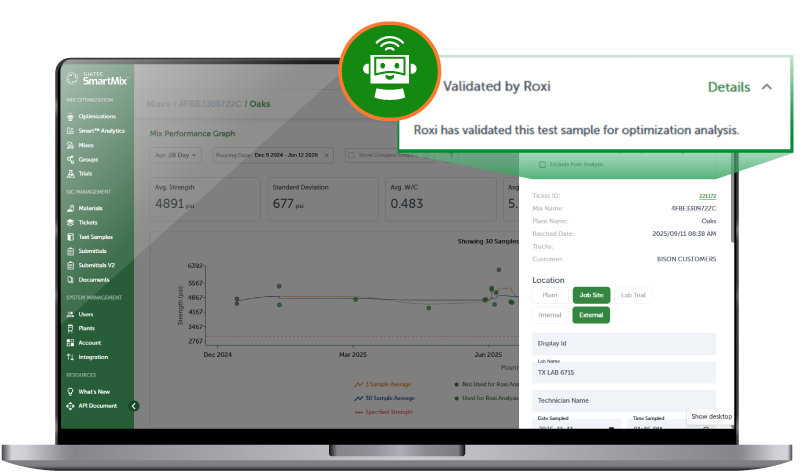

24/7 Quality Control Assistant

Roxi continuously monitors concrete test data, maturity calibrations, and mix performance in real time. Whether flagging issues or validating results, Roxi provides quality oversight without adding labor.

10x Increased Efficiency

Roxi automates the analysis and verification work that typically takes hours of manual review, delivering answers in seconds so ready-mix producers, contractors, and QC can act faster and with greater confidence.

Lower Cost, Lower Carbon

By aligning every mix to real-world performance, Roxi decreases unnecessary cement per cubic yard, helping producers cut material costs while reducing embodied carbon – all without compromising strength or quality.