Precisely monitor the temperature of your concrete structures under any conditions

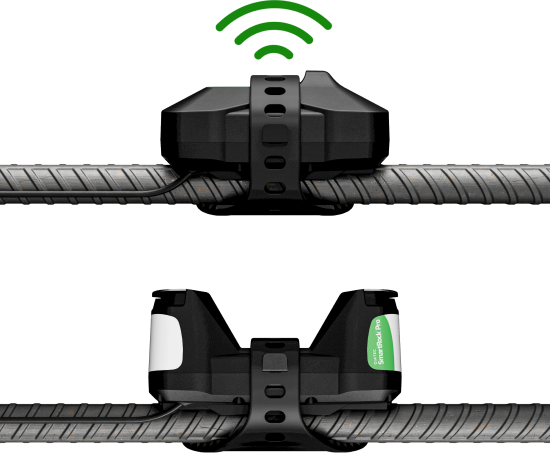

Collect real-time in-situ concrete strength data through maturity-based sensors

Maturity-Based Concrete Strength Monitoring

Self-Calibrating Concrete Strength Monitoring

AI-powered precision for every concrete mix for the Producers

Instant ROI

AI-Powered Decision Making

Drive Sustainability

Core Quality Control

Corrosion detection in concrete reinforcement

Concrete quality detection lab equipment

Quality That Travels from Plant to Pour

Devices for Measuring Rebar Corrosion, Permeability, and Resistivity of Concrete

Experts revolutionizing the construction industry

Stay on the cutting edge of concrete tech

Save the date and join us at future events and conferences

Dubai’s Law No. 7 of 2025 has introduced a new contractor classification system that redefines how contractors operate in the emirate. Dubai Municipality’s digital registry records and links every aspect of a contractor’s performance to classify them under its new, publicly accessible contractor classification law. The latest challenge for most contractors lies in maintaining up-to-date quality documentation and real-time compliance records. Dubai Municipality’s digital registry connects every aspect of a contractor’s operational performance, meaning testing delays and documentation gaps can affect classification standing. According to the AECOM Middle East Review 2025, regional construction projects experience average delays of 83% beyond schedule, with traditional 28-day concrete strength testing remaining a key contributing factor. In this blog, let’s explore how real-time concrete monitoring using the maturity method helps contractors eliminate testing bottlenecks, maintain schedules, and demonstrate quality control competency under Law No. 7. Understanding Dubai’s Law No. 7 of 2025 Issued on July 8, 2025, Law No. 7 establishes a unified contractor classification system managed by Dubai Municipality. This new framework represents a complete restructuring of how contractors are evaluated and authorized to operate in Dubai. Contractors have one year from the law’s effective date (six months after its publication in the Official Gazette) to regularize their status. Dubai Municipality may extend this period to two years in certain cases, though early compliance remains the recommended approach. The Penalty Structure The regulation establishes strict requirements for maintaining classification status. Contractors can face penalties of up to Dh200,000, potential…

The construction industry is undergoing a tech-driven transformation as artificial intelligence (AI) becomes an integral part of how we build. Long-standing challenges, from skilled labour shortages to safety risks and slim profit margins, are driving firms to adopt AI solutions to gain a competitive edge. In fact, 92% of contractors report difficulty filling open positions, contributing to project delays. Meanwhile, AI adoption is surging; 74% of AEC leaders now use AI in at least one phase of construction projects. The market for AI in construction is projected to grow from $3.99 billion in 2024 to $11.85 billion by 2029, a clear sign that AI’s impact is accelerating. In this blog, we’ll explore the key challenges AI addresses that make building projects smarter and safer, and how these innovations lead to more profitable outcomes. From intelligent concrete sensors and robotic assistants to predictive software and AI-driven project dashboards, today’s construction professionals can leverage AI for tangible benefits. Smarter Projects Through AI-Driven Insights and Analytics Modern construction projects generate massive amounts of data: blueprints, schedules, weather logs, sensor readings, and more. AI turns this data into actionable intelligence to plan and build smarter than ever before. Digital Twins and Generative Design One major advance…

At Giatec’s Concrete Tech Summit in May 2025, Mark Masotti, CEO, and Alex Hanmore, Manager of Concrete Technologies at AlterBiota made a compelling case for transforming how the industry approaches aggregate testing and the huge potential it poses for optimizing the fresh and hardened performance of concrete. Their message: it’s time to digitize aggregate testing. When paired with platforms like Giatec’s SmartMix™ and MixPilot™, digitalAggregate™ becomes a critical piece in a much bigger picture, one where optimization starts at the source and extends all the way to the pour, supporting consistent concrete workability. Concrete’s Blind Spot Traditional aggregate testing is time-consuming, low frequency, and limited in what it can measure. Most labs focus on aggregate size, using outdated but standardized methods like sieve analysis that only determine one of three dimensions. As shared by Mark, “With the sieve analysis, it would work perfectly if concrete aggregates were spheres. However, they are anything but […]. It’s the same idea that a marble and a pencil would be retained on the same sieve”. This disconnect between lab testing and field performance isn’t just theoretical, it has real cost implications. Cement overuse, rejected loads, slump variability, and water mismanagement, all stem, in part,…

Visit our careers page to learn about our award-winning culture and our open positions.

Save now and get free Giatec 360™ Premium access. Ends Dec 31. Don’t miss it!

Cut risk on mass concrete pours and get free Giatec 360™ Premium. Ends Dec 31. Don’t miss it!