The construction industry is undergoing major changes. As cities grow and emission rules get stricter, companies are reevaluating the equipment they use. In 2025, construction machinery will no longer be just about raw power. They are becoming smarter, cleaner, and more efficient than ever before.

Want to take the guesswork out of concrete slump?

Electric, hybrid, and hydrogen-powered vehicles are becoming more common. Additionally, automation and robotics are transforming how work is performed. These advancements lower costs, cut pollution, and improve safety at job sites. In this blog, we’ll explore the leading trends and provide tips for selecting the right construction vehicles and equipment.

The Rise of Electric and Clean Power Vehicles

One of the most notable shifts in construction equipment today is the move toward electric, hybrid, and hydrogen-powered machines. Global manufacturers such as Caterpillar, Volvo CE, and JCB are introducing electric excavators, loaders, and haulers that are well-suited for urban and indoor applications. These machines are ideal for urban and indoor projects where noise reduction and zero on-site emissions are critical.

Hybrid equipment is also gaining traction as a practical transition technology. By combining diesel engines with electric motors, hybrids deliver improved fuel efficiency and reduced emissions without relying entirely on charging infrastructure. This makes them well-suited for heavy-duty applications or remote job sites where battery range and charging access can still be limiting factors.

For the largest and most energy-intensive applications, hydrogen fuel cell vehicles are also being tested. These machines, such as massive haul trucks or earthmovers, can operate for long hours with the benefit of fast refueling and zero emissions. Some mining operations have already retrofitted trucks to run on hydrogen, while OEMs are testing new prototypes. Looking ahead, hydrogen-powered equipment could become a mainstream option by 2030, especially once fueling infrastructure expands to match demand.

Smarter Machines with Automation and Robotics

Self-driving equipment is being adopted more widely. Machines like bulldozers and excavators can now operate with minimal human intervention, guided by tools such as GPS and IoT sensors for precise performance all day and night. This improves productivity and enhances safety by reducing the number of workers exposed to hazardous areas.

Construction robots are also increasingly performing tasks such as bricklaying or rebar tying, while some 3D printers can build walls onsite. These tools help fill labor shortages and speed up work. With AI and machine learning, machines are getting smarter every day: avoiding obstacles, learning from tasks, and improving results.

Real-World Success Stories

Cities and companies around the world are testing and deploying electric and zero-emission construction vehicles, proving that sustainability and productivity can go hand in hand. Let’s take a look at some success stories, from municipal projects in Oslo to large-scale industrial initiatives in Sweden and the U.S., showcasing how clean machinery performs in real-world conditions.

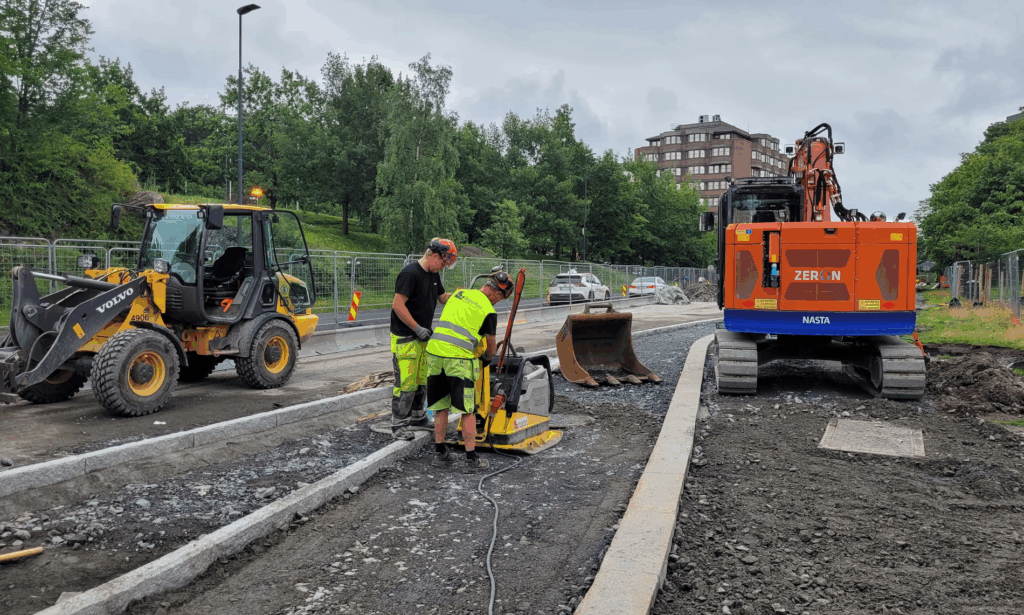

Oslo, Norway: Zero-Emission Public Works

Oslo has mandated that all municipal construction projects must use zero-emission machinery beginning January 1 2025. By 2024, about 85% of machinery on municipal construction sites was already zero-emission. These machines delivered performance comparable to diesel counterparts, while reducing noise, improving air quality, and requiring less maintenance.

Sweden: Volvo’s Electric Quarry

At the Vikan Kross quarry near Gothenburg, Volvo and Skanska conducted a 10-week “Electric Site” research project using fully electric and autonomous trucks, loaders, and excavators. The initiative achieved a 98% reduction in carbon emissions, a 70% decrease in energy costs, and a 40% reduction in operator costs. These results suggest the potential for a 25 percent decrease in total operating costs.

Los Angeles, USA: Electric Excavator Pilot by Skanska

On the Los Angeles Purple Line Transit Project, Skanska piloted a 23-ton battery-electric Volvo EC230 excavator over 90 days. The machine matched the productivity of its diesel equivalent in truck loading and earthmoving tasks. It also reduced carbon emissions by 66% and operating costs by 74% per hour. Operators reported less noise and vibration, improving comfort and communication on site.

These projects show that zero-emission machinery is already capable of replacing diesel on a variety of job sites. From Oslo’s city streets to Sweden’s quarries and large-scale infrastructure in Los Angeles, clean and automated machines are delivering the same performance while cutting emissions, noise, and costs.

Interested in sustainable construction practices? Read our guide on sustainable construction methods to see how green initiatives are reshaping the industry!

Benefits and Infrastructure Needs

The adoption of electric, hybrid, and hydrogen-powered construction vehicles is accelerating as manufacturers expand their offerings and more projects prioritize sustainability. These machines benefit urban communities by reducing on-site emissions and noise, operators by lowering fuel and maintenance costs, and companies by helping meet regulatory requirements and corporate environmental targets.

Benefits

| Benefit | Details |

| Cleaner air, lower emissions | Electric machines produce no exhaust on site, reducing CO₂ and particulate pollution. Air quality improves for workers and nearby communities. Emissions can drop by up to 95% when powered by greener electricity. Hydrogen fuel-cell machines emit only water vapor, supporting sustainability goals. |

| Lower operating costs | While upfront costs are higher, electricity is cheaper than diesel and electric motors require less maintenance (no oil changes, filters, or frequent part replacements). Fleets have reported up to 70% lower hourly costs after switching. Government incentives like tax credits and rebates can help offset purchase costs. |

| Quieter, safer, more comfortable | An electric excavator can reduce noise from 93 dB to 84 dB, which is perceived as half as loud. Less noise improves communication and reduces fatigue. Lower vibration levels also enhance comfort and safety, while making alarms easier to hear. |

By combining environmental benefits with operational savings and improved working conditions, electric, hybrid, and hydrogen-powered machines offer long-term value for contractors, project owners, and the communities where they operate.

Infrastructure Needs

Here’s the challenge: You can’t just “fill up” an electric machine like you do with diesel. For construction planning, this shift means accounting for new infrastructure needs, such as charging stations or hydrogen refueling points, and aligning project schedules with the capabilities of alternative powertrains. It also requires evaluating fleet composition to balance performance, energy availability, and total cost of ownership as the industry moves toward cleaner and more efficient operations. Let’s take a look at each of these requirements.

| Requirement | Description |

| Charging stations | Small equipment may use a basic grid connection, but larger machines require high-powered chargers. Remote sites may need solar trailers, battery banks, or diesel generators to keep fleets operational. |

| Hydrogen fueling | Limited public fueling options mean some contractors create hydrogen on site via electrolysis or bring mobile fueling trailers. Manufacturers like JCB offer mobile hydrogen refuelers for direct on-site service. |

| Early planning | Consider charging or fueling locations, time requirements, and portable power solutions before purchasing machines. Infrastructure readiness is as important as the equipment itself. |

By addressing infrastructure needs early, contractors can fully realize the benefits of green equipment while minimizing downtime and operational challenges.

What Leaders Need to Know

If your company is moving toward electric or hydrogen, plan your infrastructure early. Where will you charge or refuel? How long will it take? Do you need portable power solutions? The answers to these questions are as important as the machine you buy.

Want to hear experts discuss the future of green construction? Listen here!

Top 10 Essential Construction Vehicles (Types & Uses)

Every construction project relies on a core set of heavy machines to get the job done efficiently and safely. From digging foundations to moving materials, each piece of equipment has a role to play. Here’s a breakdown of the 10 most essential construction vehicles, their key uses, and tips for selecting the right machine for your site:

1. Excavators

Excavators are large boom-arm machines equipped with buckets, designed for digging trenches, foundations, and moving soil or rubble. They come in a range of sizes from mini to massive and offer 360° rotation. Uses include excavation, demolition (with hammer attachments), and material handling. When selecting an excavator, tracked models provide better traction on soft or uneven terrain, while wheeled excavators are faster on hard surfaces. Choose the size based on site constraints and dig depth, and consider attachments such as grapples or breakers for added versatility.

2. Bulldozers

Bulldozers are powerful tracked tractors with broad front blades, essential for pushing earth, grading land, and clearing debris. They are commonly used for land clearing, rough grading, slope creation, and road or path cutting. Tracks spread weight effectively, making bulldozers ideal on soft ground or slopes. Selecting the right blade and ripper depends on the hardness of the material. Larger bulldozers move more material quickly, while smaller models are more agile in confined spaces. For cold climates, enclosed cabs and block heaters improve operator comfort and machine reliability.

3. Backhoe Loaders

A backhoe loader combines a rear digging arm with a front loading bucket, effectively offering two machines in one. Uses include trenching, excavation, and lifting or moving materials, making them suitable for utility work, landscaping, and small construction projects. Wheel-driven backhoes can travel on roads between sites, and compact dimensions or all-wheel steering help maneuver in tight urban spaces. When selecting a backhoe, consider digging depth (typically 14–17 feet) and breakout force to ensure it meets project needs.

4. Wheel Loaders (Front Loaders)

Wheel loaders are equipped with large front buckets to scoop and move bulk materials such as soil, gravel, or construction debris. They are essential for loading dump trucks, stockpiling materials, and general site cleanup. Selection depends on project size: compact loaders are ideal for confined or indoor spaces, while larger loaders improve efficiency on large infrastructure or mining projects. Consider tire type and tread for rough or debris-filled sites. Electric wheel loaders are now available and significantly reduce noise and emissions, which is especially beneficial in urban or indoor environments.

5. Dump Trucks (Haulers)

Dump trucks transport large volumes of materials, including soil, sand, gravel, or demolition debris, either around the site or off-site. Types include on-road trucks for site-to-dump transport and articulated trucks for rough terrain. Key selection criteria include capacity and maneuverability. Articulated dump trucks handle soft or uneven terrain better, while standard trucks are suitable for longer-distance or highway hauling. Ensure load capacity matches site needs, and consider engine and brake specifications for steep grades, cold climates, or mountainous terrain.

6. Cranes (Mobile Cranes)

Cranes lift and place heavy materials, such as steel beams, precast concrete, or equipment. Mobile cranes, mounted on trucks or rough-terrain chassis, provide flexibility on-site, while tower cranes dominate tall building projects. Selection should focus on crane capacity relative to the heaviest load and required lift radius. Rough-terrain or crawler cranes are ideal for uneven or rugged sites. It’s also important to account for local regulations, including road permits for transport and adequate outrigger setup space.

7. Motor Graders

Motor graders have long, adjustable blades for fine grading, creating smooth surfaces, spreading base material, or performing snow removal. They are commonly used for roadwork, large site leveling, and drainage slope creation. When choosing a grader, consider blade width and machine power. Compact graders are more maneuverable in tight areas, while GPS grade control systems enhance precision and efficiency. Ensure the grader’s engine and hydraulic systems are rated for extreme climates or high-altitude conditions.

8. Compactors/Rollers

Compactors and rollers compress soil, gravel, or asphalt to create stable surfaces. Types include smooth-drum rollers for asphalt and granular soils, padfoot rollers for clay, and pneumatic (rubber-tire) rollers for finishing. Selection depends on the material and area size. Vibratory smooth-drum rollers are ideal for granular soils, while padfoot rollers work best on cohesive soils. Smaller walk-behind rollers suit narrow trenches or small lots, whereas large double-drum rollers are needed for highways. Electric or hybrid rollers can reduce noise and emissions in urban or sensitive sites.

9. Concrete Mixer Trucks

Concrete mixer trucks transport and continuously mix concrete from the batching plant to the construction site, ensuring it remains ready to pour. They are essential for foundations, slabs, and columns. Proper planning requires matching the number and size of mixer trucks to the pour rate—too few trucks risk concrete setting too soon, too many incur idle costs. For high-rise or difficult-access sites, additional equipment such as concrete pumps may be necessary. City mixers navigate tight streets more effectively, and scheduling with the batch plant ensures consistent concrete quality.

To further improve efficiency, technologies like Giatec MixPilot™ can be integrated into fleets. MixPilot wirelessly monitors concrete during transit, measuring parameters such as slump and temperature in real time. This allows contractors to detect inconsistencies before arriving on site, minimize rejected loads, and ensure each batch meets specifications, helping maintain consistency and quality from the plant to the pour.

10. Telehandlers/Forklifts

Telehandlers combine features of cranes and forklifts, with telescopic booms and attachments for lifting and placing materials. Standard forklifts handle palletized materials on smooth surfaces. Uses include lifting pallets of bricks, lumber, or other materials to upper floors, moving materials around the site, and reaching into buildings. Selection depends on maximum lift height, load weight, and terrain. Telehandlers may require stabilizers for high lifts, and electric forklifts are ideal for indoor or finished-floor work. Always verify load charts to prevent accidents or damage.

Want to take the guesswork out of concrete slump?

Choosing the Right Vehicle for Your Project

Choosing the best construction vehicle means balancing more than just task performance. Terrain, climate, emissions rules, and client expectations all play a role in picking equipment that improves safety, lowers costs, and boosts efficiency.

Terrain and Mobility

Project location matters. Tracked machines like excavators and bulldozers are best for muddy or uneven ground, offering better traction and stability. Wheeled equipment like backhoes and loaders works well on firm, urban surfaces. On sloped or rugged terrain, articulated dump trucks provide flexibility and control, making them ideal for large-scale highway or earthmoving jobs.

Climate and Working Conditions

Weather affects performance. Diesel machines may need block heaters and treated fuel in cold climates, while electric machines can start more reliably in freezing temperatures, especially useful for indoor or high-altitude sites. In hot zones, both fuel types require cooling systems that can handle extended operation.

Local Rules and Emissions

Cities across North America and Europe are tightening emissions and noise regulations. Contractors relying only on diesel risk fines, permit issues, or lost bids. Electric and hybrid machines help meet clean-air mandates and noise limits, essential for urban projects like those in New York or London.

Fleet Planning: Mixing Diesel and Electric

Rather than replacing entire fleets, many firms use a blended approach. Diesel remains useful for remote or long-shift work, while electric models are ideal for short, urban, or indoor tasks. This hybrid strategy helps reduce emissions, streamline maintenance, and lower total ownership costs.

Meeting Client Expectations

Clients increasingly expect sustainable practices. Low-emission fleets can give contractors a competitive edge, especially on government or green-certified jobs. Offering the right mix of equipment shows a forward-thinking mindset and positions your business as a leader in responsible construction.

Electric vs. Diesel: Cost, Performance, and ROI

In 2025, many contractors are asking the same question: Should I invest in electric vehicles or stick with diesel? Both options have pros and cons. Here’s a clear breakdown to help you decide.

Costs, Operation, and Performance

| Factor | Electric | Diesel |

| Upfront Cost | Higher initial cost due to batteries and new technology, sometimes nearly double the price of diesel. Prices are decreasing and rebates can help close the gap. | Lower purchase price today with fewer upfront incentives, but more exposed to future price increases. |

| Operating Costs | Lower ongoing costs. Electricity prices are more stable, and maintenance needs are reduced. Some fleets report up to a 74% drop in hourly operating costs. | Higher fuel and maintenance costs due to oil changes, filters, and more complex engines. |

| Power and Runtime | Comparable torque and performance for most jobs with smoother operation. Shorter runtime between charges, but fast charging or battery swaps can keep work moving. | Longer runtime between refuels, ideal for remote or all-day projects where downtime is costly. |

Comfort, Emissions, and Use Cases

| Factor | Electric | Diesel |

| Noise and Comfort | Quieter operation with less vibration, improving communication, operator comfort, and suitability for noise-sensitive sites. | Louder with more vibration, which can lead to operator fatigue and restrictions in certain areas. |

| Emissions and Regulations | Zero emissions onsite and significantly lower greenhouse gas emissions overall (60–95% less depending on energy source). Meets sustainability targets and complies with stricter regulations. | High emissions of CO₂, NOx, and particulates, which may lead to penalties or restrictions in regulated areas. |

| Return on Investment (ROI) | Higher upfront cost but faster payback in high-use or high-fuel-cost regions. Resale values are rising as demand grows. Enhances brand and attracts environmentally conscious clients. | Strong resale value today but slower payback in most regions. Less alignment with sustainability goals and emerging regulations. |

| Best Use Case | Ideal for frequent use, urban or noise-sensitive sites, and companies seeking sustainability advantages. | Best for long-haul, heavy-duty, and remote projects where extended runtime is critical. |

For maximum efficiency, a hybrid fleet strategy works best: diesel powers remote or heavy-duty tasks, while electric machines handle short, urban, or environmentally sensitive projects. Combining diesel and electric equipment allows contractors to maximize efficiency, reduce environmental impact, enhance site safety, and future-proof their operations.

Conclusion

In 2025, construction vehicles powered by electricity, hydrogen, or hybrid systems are becoming more widespread. They’re being used every day to cut emissions and save money. At the same time, robots and smart systems are making job sites safer and helping work move faster. Automation and robotics are enhancing productivity and safety. Contractors need to plan fleets strategically, ensure adequate charging or refuelling infrastructure, and take advantage of incentives to support the transition. Companies that act now will gain operational advantages, strengthen public trust, and be better prepared for the regulatory and market shifts ahead. The transition is already underway, those who lead it will define the industry’s next chapter.