Governments and builders are under pressure to meet climate goals. But that doesn’t mean giving up performance. The good news? Many of today’s top building materials are stronger, cleaner, and smarter.

Move Data Center Projects Faster

Construction professionals are working under increasing pressure to meet both performance and sustainability targets. In 2025, the materials we use matter more than ever. That’s because buildings are responsible for about 37% of the world’s energy-related CO₂ emissions.

In this blog, we’ll explore 10 materials changing the way we build. These innovations are helping improve energy efficiency, extend service life, and reduce environmental impact while remaining practical for today’s jobsite.

1. Carbon-Neutral Concrete

Concrete is one of the most-used building materials on Earth but its environmental impact is significant. Cement production alone is responsible for around 8% of global CO₂ emissions.

Several companies are developing ways to lower this footprint. Some now inject captured CO₂ into fresh concrete. This carbon stays locked inside, reducing emissions without hurting strength. Others are making cement-free concrete, using materials like steel slag or fly ash instead.

Another example is CarbiCrete, which uses steel slag and CO₂ curing to make carbon-negative concrete, it removes more carbon than it emits.

As more builders use low-carbon mixes, tracking strength on-site becomes critical. Real-time tools now let crews monitor curing. This helps them remove formwork at the right time, cut delays, and avoid using more cement than needed.

A batch plant near the MetPark site helps lower the concrete’s carbon footprint. Photo courtesy of Miller & Long

2. Self-Healing Concrete

All concrete cracks over time. But now, some cracks can heal themselves.

Self-healing concrete uses bacteria or special chemicals mixed into the concrete. When water seeps into a crack, these agents activate. The bacteria produce calcium carbonate, which fills the crack just like how a scab heals a cut.

This technology was first developed at TU Delft in the Netherlands. It’s already been used in Amsterdam’s canals, where fixing concrete is hard and expensive.

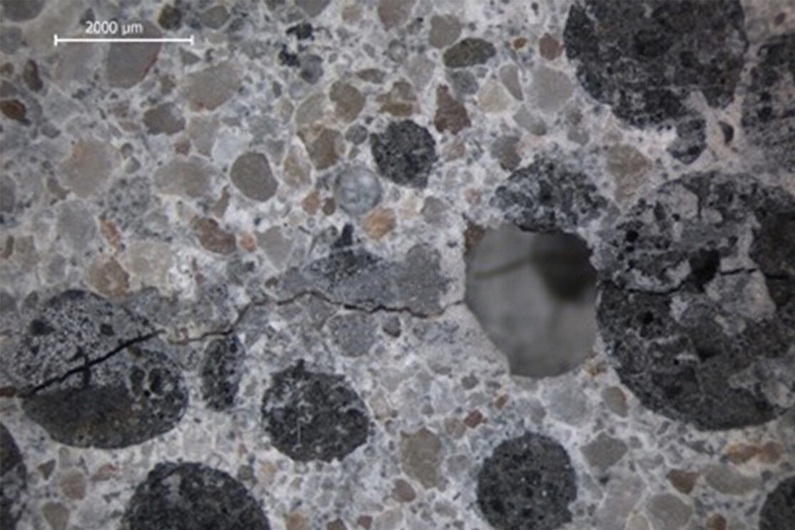

Cracked concrete before self-healing

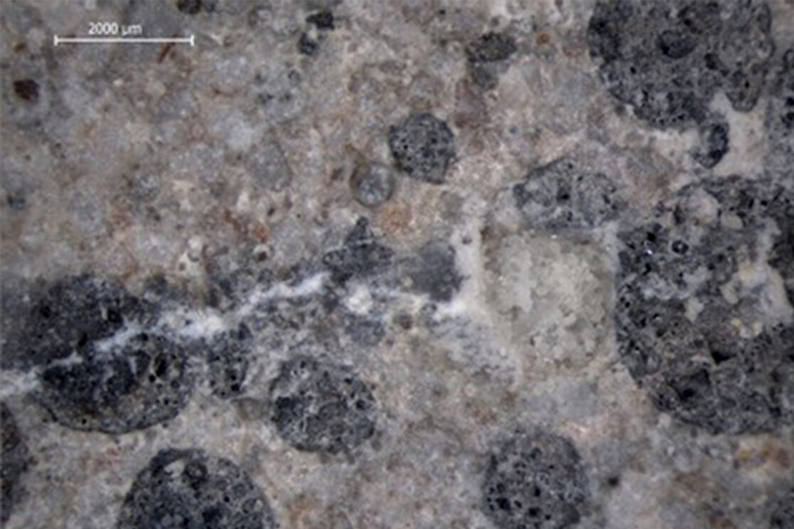

Cracked concrete after healing

Over time, this kind of concrete could save a lot of money and reduce waste. Fewer repairs mean less material used, and longer-lasting structures. That’s good for bridges, tunnels, and even buildings in wet or salty climates.

As the tech grows, builders are pairing it with real-time monitoring tools. These tools help teams see how well the concrete is curing. In the future, they could even confirm when healing happens making buildings smarter and more reliable

3. Cross-Laminated Timber (CLT)

Cross-laminated timber (CLT) is a strong wood panel made by gluing layers of lumber at right angles. This crisscross design makes it strong enough to replace concrete or steel in many buildings. It’s also much lighter and has a lower carbon footprint.

CLT panels are built in factories and shipped to job sites. They go together like a kit, making buildings faster and cleaner to build. Less waste, fewer workers, and shorter timelines make CLT a smart choice.

Ascent MKE, world’s tallest cross-laminated timber hybrid building. Photo Courtesy of KAA Design Group / Nairn Olker

A great example is Ascent MKE in Milwaukee – a 25-story mass timber tower completed in 2022. It’s the tallest of its kind and shows how wood can be safe, strong, and beautiful.

In Canada, there are already 600+ mass timber buildings, with more being planned. CLT is renewable, stores carbon and performs well in fire when designed properly.

4. Engineered Bamboo

Bamboo isn’t just for scaffolding anymore. It’s now one of the top green building materials of 2025.

Engineered bamboo is gaining attention as a lightweight, renewable alternative to traditional construction materials. While trees can take decades to mature, bamboo grows in 3–5 years and regrows without replanting.

Builders turn bamboo into beams, panels, and flooring by pressing treated strips together. These products meet building codes and hold up well in damp climates. Projects like the Green School in Bali use bamboo for frames and trusses. In North America and Europe, it’s showing up in floors, walls, and even structural studs.

The bamboo nursery classroom with bent beams and a radial roof system, designed for young learners in a naturally lit and breathable structure. Photo Courtesy of Will Cottrell Art

Bamboo is also a carbon sink that absorbs CO₂ as fast as it grows. But like any natural material, it needs proper treatment to last and stay insect-free. Still, when handled right, it’s tough, flexible, and even helps in earthquakes.

5. Recycled Steel

Steel is one of the world’s most recycled materials and a smart choice for green construction in 2025.

Making steel from recycled scrap uses up to 75% less energy than making it from raw materials. Some factories now even run on clean electricity, which makes their steel even more eco-friendly.

Recycled steel is just as strong as new steel. It’s used in beams, rebar, panels, and frames for everything from homes to bridges.

A great example is the Centre Block Rehabilitation Project in Ottawa. Engineers reused nearly 1,700 steel beams from the original Parliament building. This smart reuse saved around 625 metric tons of CO₂ and kept the project more sustainable.

Photo Courtesy of Construction Connect

Recycled steel also helps keep costs stable, since scrap is widely available. For large or complex buildings, it remains one of the best-performing and greenest materials around.

6. Smart Glass and Solar Windows

Advances in glass technology are helping buildings operate more efficiently. Smart glass can darken or lighten automatically, depending on the sun. That cuts glare and reduces cooling costs by up to 30%. No need for blinds or shades, the glass handles it on its.

Even more exciting are solar windows. These look like regular glass, but they generate electricity using invisible light. Perfect for tall buildings, skylights, and glass railings.

View, Inc. has installed smart windows in airports and offices across North America including San Francisco International Airport.

At Michigan State University, researchers have installed transparent solar coatings that turn buildings into vertical solar panels, creating power from sunlight without blocking the view.

In 2025, these advanced windows are showing up in more real-world buildings, saving energy and boosting design at the same time.

Transparent solar glass window panels are now transforming ordinary windows into clear power sources. Image Unsplash

7. Graphene-Enhanced Concrete

Graphene is a carbon-based material with extremely high strength and conductivity. When added in tiny amounts to concrete, graphene makes it stronger and more water-resistant. Studies show that concrete with graphene can be 2.5 times stronger and 4 times less porous than regular mixes. That means bridges, roads, and buildings that last longer and need fewer repairs.

Detail of 3D printed Island Steps, build with Versarien’s trademarked product Cementene. Photo Courtesy of Graphene Flagship

In the UK, a test project called Concretene showed that graphene mixes could cut cement use by 15–30%, saving CO₂ emissions without losing strength.

Graphene also helps create smart concrete. Since it conducts electricity, graphene mixes can be used to build self-heating sidewalks or monitor cracks in real time.

It’s also used in paints, sealants, and even asphalt, making surfaces stronger and more resistant to water, heat, and wear. In Italy, roads built with graphene asphalt are already holding up better under traffic.

As production grows and prices drop, graphene is becoming a powerful way to make materials stronger and smarter while using less.

8. Fiber-Reinforced Polymers (FRPs)

Fiber-Reinforced Polymers (FRPs) are lightweight but strong materials used to replace steel in many construction projects. They are made of fibers like glass, carbon, or basalt, held together in a plastic resin. FRPs are very strong in tension, don’t rust, and weigh about one-fourth as much as steel. That makes them easier and safer to carry, cut, and install on-site.

One example is GFRP rebar. It is used in places where steel would normally corrode, like roads, bridges, or marine areas. The Floodway Bridge near Winnipeg, built in 2006, used over 400 km of GFRP rebar. After almost 20 years, it still shows no signs of corrosion.

FRPs are also used for:

- Wrapping old concrete columns to make them stronger (like duct tape for buildings)

- Making beams for pedestrian bridges or cooling towers

- Reinforcing buildings in earthquake zones

FRPs don’t carry electricity or magnetic fields, which makes them ideal in places like MRI rooms or chemical plants.

Though once expensive, prices are dropping, and more design codes now include FRPs. In 2025, over 500 bridges worldwide use FRPs, a clear sign these materials are becoming mainstream.

Move Data Center Projects Faster

9. Modular Building Systems

Instead of building everything on-site, modular systems are built in factories, then moved and assembled on location. These modules can be full rooms, even entire apartment units, and they go up much faster than traditional builds.

Factory work means better control, less waste, and faster timelines. Crews use smart materials like engineered wood, light-gauge steel, and insulated wall panels. Some even come with sensors already installed to track curing and strength once they’re placed on-site.

A great example is the Nexii’s Starbucks café in Abbotsford, Canada. It was built in just 6 days using low-carbon panels and produced almost zero construction waste. Builders can also use BIM (Building Information Modeling) to design and plan each module before anything is built. This helps reduce errors and delays.

This Starbucks café was constructed in just six days with pre-finished Nexii panels forming the wall and roof. Photo courtesy of Nexii, Inc.

In 2025, modular methods are being used for everything from hotels and schools to hospitals and homes, offering faster, cleaner, and smarter ways to build.

10. Green Roofs and Living Walls

Some of the most exciting building “materials” aren’t materials at all, they’re living things.

Green roofs are rooftops covered in plants. They include special layers to hold soil, water, and drought-tolerant greenery like grasses, sedum, or wildflowers. These roofs help cool buildings, reduce stormwater runoff, and clean the air.

In Toronto, new large buildings are required to include 20–60% green roof coverage. Today, the city has over 1 million square meters of green roofs.

The Form at 50 McCaul, one of more than 1000 green roofs implemented in Toronto. Photo Courtesy of Greg VanRiel/NLSM

Living walls or vertical gardens, which are mounted vertically along interior or exterior walls, offer similar benefits. They can be simple vines or high-tech hydroponic systems. Outdoors, they reduce heat on building surfaces by up to 10°C. Indoors, they clean the air, control humidity, and boost well-being.

Green roofs and walls also support birds, bees, and other wildlife. With proper design and support, they can turn cities into cleaner, greener places one surface at a time.

Choosing the Right Building Material: Concrete vs Timber vs Steel

With all these new materials, one big question still comes up on job sites and in design meetings: What’s the best material to build with?

There’s no one-size-fits-all answer. It depends on the project, the climate, the budget, and even how fast you want to build. But for most structures, the choice comes down to three main options: concrete, timber, and steel. Each has strengths, weaknesses, and the right place to shine.

Let’s break it down.

Concrete

Known for its strength, durability, and fire resistance, concrete is a staple in foundations, basements, and heavy infrastructure. However, traditional cement production contributes significantly to carbon emissions. Newer mixes are helping to reduce this impact. It’s moderately priced, but costs can fluctuate with cement demand.

Mass Timber (CLT)

Mass timber, including CLT, is a renewable, lightweight material that allows for faster construction. It stores carbon and offers a natural aesthetic, making it a strong option for schools, residential buildings, and mid-rise structures. It performs best in dry climates and is often cost-competitive with concrete when time savings are considered.

Steel

Steel is ideal for long spans, high-rises, and industrial projects due to its high tensile strength and recyclability. Prefabricated components allow for quick on-site assembly, though it may require coatings to prevent corrosion. While initial costs can be higher, its precision.

| Material | Best For | Pros | Cons | Environmental Impact | Cost |

| Concrete | Foundations, bridges, basements, heavy-load structures | Strong in compression, fire-resistant, durable, widely available | High carbon footprint without SCMs or CO₂-reduction methods | High unless low-carbon mix is used | Moderate; affected by cement market demand |

| Mass Timber (CLT) | Mid-rise buildings, schools, residential projects, hybrid structures | Renewable, lightweight, quick to install, stores carbon, aesthetic appeal | Limited in span and height, fire codes vary, sensitive to moisture | Very low if sourced sustainably | Competitive with concrete, especially when time savings are factored in |

| Steel | Long spans, high-rises, industrial buildings, prefabricated projects | Strong in tension, recyclable, manufactured with precision, fast on-site assembly | Prone to corrosion without protection, higher embodied energy | Moderate; improves when recycled steel is used | Variable; often higher upfront but reduces on-site labor time |

Want to learn more about the pros and cons of wood vs. concrete? Read here!

Conclusion

Choosing the right materials is a key factor in achieving better project outcomes, whether it’s through durability, sustainability, or cost-effectiveness. While traditional materials still form the backbone of many projects, new options are helping improve performance and reduce environmental impacts across the lifecycle of a structure.

The examples in this blog reflect ongoing efforts to enhance construction through thoughtful innovation. As these materials become more accessible, they offer promising solutions for addressing today’s construction challenges and preparing for those ahead.