The concrete industry is under growing pressure. Producers must maintain high-quality standards while also reducing costs, material waste, and carbon emissions. Traditional mix management methods lack adaptability, as they rely on outdated, manual, and reactive processes. In this context, Giatec’s Roxi™ emerges as a powerful example of Concrete AI, reshaping how producers manage and optimize their mixes. In this blog, let’s take a look at how Giatec’s AI assistant supports concrete production.

Want to take the guesswork out of concrete slump?

The Challenges of Traditional Mix Management

To begin, concrete producers face major daily challenges: raw material variability, strict specs, and limited real-time visibility. Most producers overdesign by 600–700 PSI, resulting in the overuse of about 80 lbs of cement per cubic yard on average, according to the NRMCA yearly quality survey. These inefficiencies lead to higher production costs, environmental impacts, and underutilization of available resources.

Traditional methods lack adaptability and agility, primarily because they’re built around outdated, manual, and reactive processes. Furthermore, testing and adjustments are infrequent and often disconnected from real-time conditions, resulting in overdesign, increased variability, and reduced profitability.

Meet Roxi: Giatec’s Concrete AI Assistant

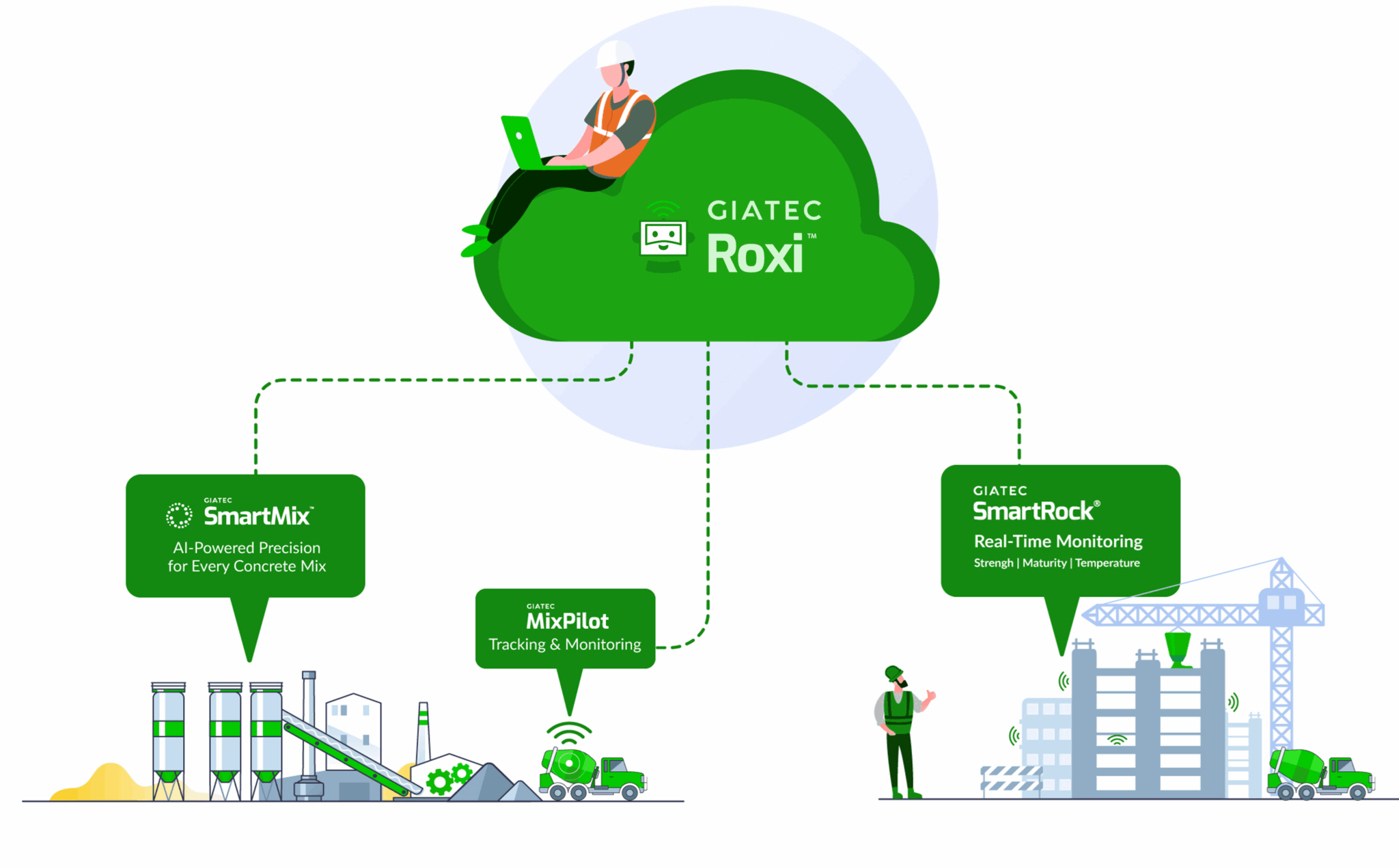

Roxi tackles key problems like overdesign, slump variability, underperformance, and reactive quality control. It continuously analyzes data from plants, in-transit sensors like MixPilot™, and raw material suppliers, delivering insights through Giatec SmartMix™. The program was built for Giatec’s patented, award-winning SmartRock® wireless concrete sensor. This data includes detailed measurements across the concrete production, delivery, and utilization cycles, including batch records, delivery trends, water addition, material changes, performance measurements, and even environmental factors like temperature and humidity. Through advanced algorithms, Roxi then translates these data points into precise, actionable insights and predictive optimization.

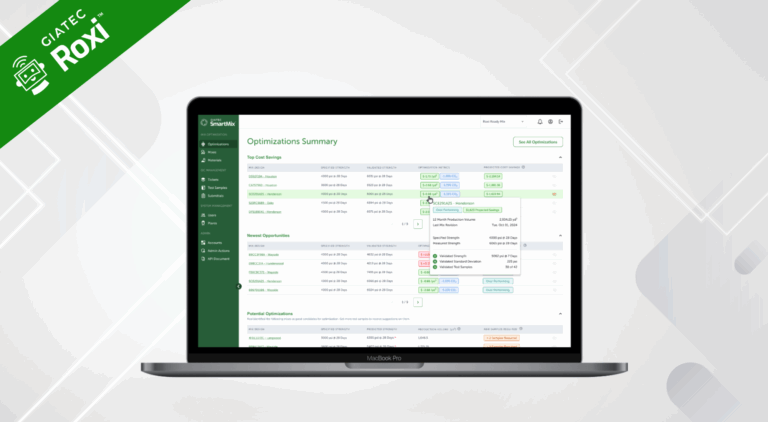

Roxi’s intelligence is deployed through SmartMix, which serves as a central hub for all concrete performance data. Beyond optimization, Roxi’s advanced calculations are applied across several quality control functions to deliver deeper insights and smarter decision-making across the board.

Want to take the guesswork out of concrete slump?

How Roxi Enhances Concrete Production

- Reducing Overdesign and Material Costs: Roxi systematically reduces the overdesign inherent in traditional concrete mixes by precisely recommending adjustments based on actual performance data. Roxi helps producers save $1.20–$2.00 per cubic yard, cutting waste and boosting margins.

- Real-Time Data and Predictive Insights: Unlike reactive methods, this Concrete AI assistant constantly reviews live data. As a result, teams can quickly spot and resolve variability or emerging issues. Roxi learns from both historical and real-time data, delivering accurate predictions and actionable insights.

- Improved Mix Consistency and Performance: Roxi standardizes quality across batches. This consistency reduces variability in concrete strength, slump, and air content. It also enables producers to meet specs while reducing costly trial and error.

- Optimizing Testing and Resource Allocation: Roxi strategically informs producers where and how often to conduct concrete testing, maximizing the value of quality control efforts. SmartMix makes this process seamless by housing all mix and performance data in one centralized platform. As a result, Quality Control teams can track trends, compare mix designs, and apply Roxi’s suggestions.

Every recommendation is tracked, giving producers real-time insight into the cost and CO₂ implications of every adjustment. One click lets them accept an optimization recommendation, whether it includes mix re-design, mix adjustments, changes to admixture utilization, or an aggregate re-blend. Scenario tools compare mix options before rollout, helping teams turn Roxi’s insights into confident, data-backed decisions.

Proven Results from Leading Concrete Producers

Leading concrete producers have already experienced Roxi’s transformative impact. Modern Concrete & Materials optimized 19% of their production leveraging Roxi’s insights, saving $1.26 per cubic yard on average. Similarly, Tomlinson Ready Mix successfully optimized 22% of their production, securing cost savings averaging $1.53 per cubic yard and substantial reductions in their CO₂ footprint.

Together, these cases illustrate the power of Roxi’s AI and SmartMix’s mix management capabilities, to deliver significant cost efficiencies, improved operational performance, and meaningful environmental benefits, positioning producers as forward-thinking leaders in modern concrete production.

The Future of Roxi™ and Concrete AI Optimization

As powerful as Roxi is today, the potential for AI-driven optimization in concrete production continues to grow. Giatec is actively advancing Roxi’s capabilities to include:

- Enhanced Integration with Digital Ecosystems: Roxi will increasingly integrate with dispatch, telematics, and third-party monitoring systems, closing the loop between mix design and actual field performance.

- Expansion of Large Language Models (LLMs): Upcoming developments will incorporate large language models, enabling producers to interact dynamically with their data. This will allow for instant, detailed, and customized reporting, making critical operational insights accessible in real-time.

- Increased Autonomy and Predictive Analytics: Roxi will deliver deeper mix behavior predictions. Moreover, it will automatically suggest proactive mix adjustments to meet performance targets.

The future of concrete production lies in connected, intelligent platforms like SmartMix, powered by Roxi. SmartMix empowers producers to unlock the full potential of their data, unlocking efficiency and profitability. By moving away from manual processes and toward integrated, AI-powered systems, producers can turn quality control into a competitive advantage, setting new benchmarks for excellence.

Curious about how Roxi delivers value beyond mix optimization? Book a consultation with one of our experts today!