Smart cities are no longer a futuristic idea. They’re being built now, transforming how we live and how we build. These tech-driven cities use data to solve real urban challenges, from traffic to energy to climate impact. As they take shape, the role of construction becomes more central than ever. Every smart utility, transit line, and high-performance building must first be constructed, and that work starts with contractors and engineers.

Build Data Centers Faster with SmartRock® Long Range

The shift is already underway. Cities around the world are investing in smart infrastructure at record pace. For construction teams, that means new expectations, new tools, and new project types. In this blog, let’s take a look at how smart cities represent an opportunity for the industry, changing what we build, how we build it, and who gets to lead the future of urban development.

What Makes a City “Smart” And Why Construction Is at the Core?

At its core, a smart city uses technology and data to improve how people live. This includes tools like IoT sensors, AI-powered analytics, smart energy systems, connected transit, and digital public services. These systems work together to make cities more efficient, sustainable, and responsive. For example:

- Sensors can detect water leaks underground or adjust traffic lights in real time.

- AI platforms analyze city data to optimize energy use and public services.

- Smart grids and connected transit systems create more efficient, sustainable communities.

But none of this exists without construction. If technology is the brain of a smart city, then construction is its backbone. Every smart feature relies on infrastructure: roads, bridges, utilities, and buildings, that must be planned and built to support it. Smart grids require new power systems. Connected transit needs new stations and lanes. Even digital services depend on cables, towers, and sensors installed during construction. This means contractors and engineers aren’t just building structures, they’re embedding intelligence from the ground up.

The industry is stepping up. What was once a bricks-and-mortar field is now embracing sensors, automation, and AI as part of standard practice. Smart construction is driving this change, installing technology during builds, using data-rich models, and choosing materials that support long-term sustainability. Without this shift, smart cities would remain ideas on paper. By adapting to include digital infrastructure in our projects, we’re literally laying the foundation for smarter cities.

Smart Technologies on the Ground: Tools That Are Changing the Jobsite

Smart construction is already part of everyday builds. Digital tools and intelligent systems are reshaping how crews work, helping projects move faster, safer, and with fewer errors. Here are some of the technologies making the biggest impact on jobsites today:

IoT and Real-Time Sensors

- Wireless monitoring: Sensors now track everything from equipment usage to concrete curing in real time. Giatec’s SmartRock®, monitors concrete strength continuously so forms can be removed sooner, keeping schedules on track.

- Faster decisions: Data flows directly to project teams, reducing delays and cutting out guesswork.

AI and Data-Driven Software

- Mix optimization: SmartMix™ uses AI to fine-tune concrete mixes, cutting cement use and reducing carbon emissions.

- Quality control: MixPilot™ uses smart sensors on concrete trucks to track the concrete’s properties (like slump) from the batch plant to the jobsite in real time. This ensures the concrete hasn’t over-hydrated or lost workability en route, preventing quality issues before the pour.

- Beyond concrete: AI-based project management tools can analyze schedules to predict delays or cost overruns, helping project managers make informed decisions early.

BIM and Digital Twins

- 3D clarity: Building Information Modeling (BIM) creates detailed models that align architects, engineers, and builders. Today’s BIM models are rich with data and can simulate how a building will perform before it’s built. This is hugely beneficial in smart city projects where infrastructure systems (power, water, telecom, etc.) are highly integrated

- Digital twins: Some cities go a step further and develop digital twins, virtual replicas of buildings or infrastructure that update in real time with sensor data. These twins can be used during construction and after completion to monitor performance. For instance, Singapore has experimented with digital twin models of entire districts to simulate traffic flow and energy usage.

- Aerial perspective: Drones now survey sites and track progress with aerial photos, creating accurate 3D maps in hours – a task that used to take days of manual measuring.

- Automation in action: Robotics are also emerging, from robot bricklayers to rebar-tying robots to handle repetitive tasks with precision

- New techniques: 3D printing is being used to fabricate building components with less waste, while emerging materials like self-healing concrete boost long-term durability.

The modern jobsite is evolving into a high-tech environment where IoT-enabled tools are transforming concrete testing and mixing into streamlined digital processes. With these new technologies, projects are delivered faster, safer, and with higher quality. Mastering these tools is becoming as essential as traditional construction skills, driving the industry toward fully smart construction and smarter cities.

Interested in how digital twin technology is revolutionizing infrastructure design and maintenance? Read our blog on Concrete Technologies here!

Real-World Smart City Case Studies

Seeing real-world projects is the best way to understand how smart cities are reshaping urban development. Let’s take a look at four real-world projects that show how technology, sustainability, and construction are coming together to shape the cities of tomorrow.

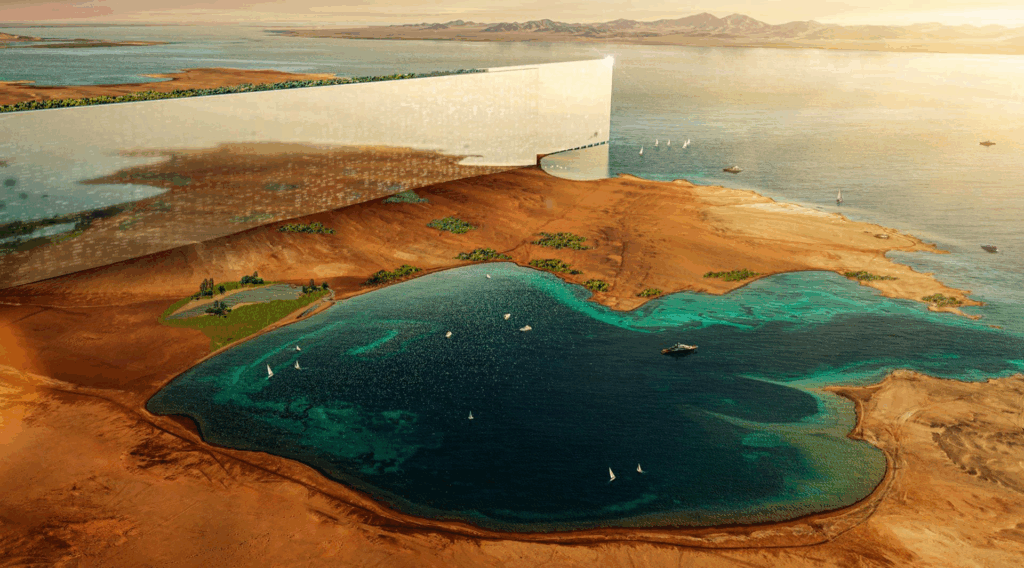

NEOM, Saudi Arabia

NEOM is one of the most ambitious smart city projects in the world. This $500-billion development in northwest Saudi Arabia is not just a single city but an entire high-tech region, including a linear city called The Line. Designed as a special economic and technology zone, NEOM aims to attract global talent and investment, with AI managing systems from energy to transportation to security. Renewable energy will power the entire region, and infrastructure is built from the ground up to enable autonomous transit and drone deliveries from day one.

For engineers and builders, NEOM is both a playground of innovation and a massive challenge. During construction of its extensive tunnel network, teams used SmartRock sensors during tunnel construction to track concrete curing in real time, allowing work to continue without waiting days for lab results. NEOM demonstrates how an integrated approach, planning infrastructure, buildings, and technology systems together, can transform visionary designs into reality. The project has become a benchmark for pushing smart city concepts to their limits, showing that cutting-edge construction techniques and materials are essential to realizing ambitious urban visions.

Want to learn more about how SmartRock was used in the NEOM project? Read the full case study!

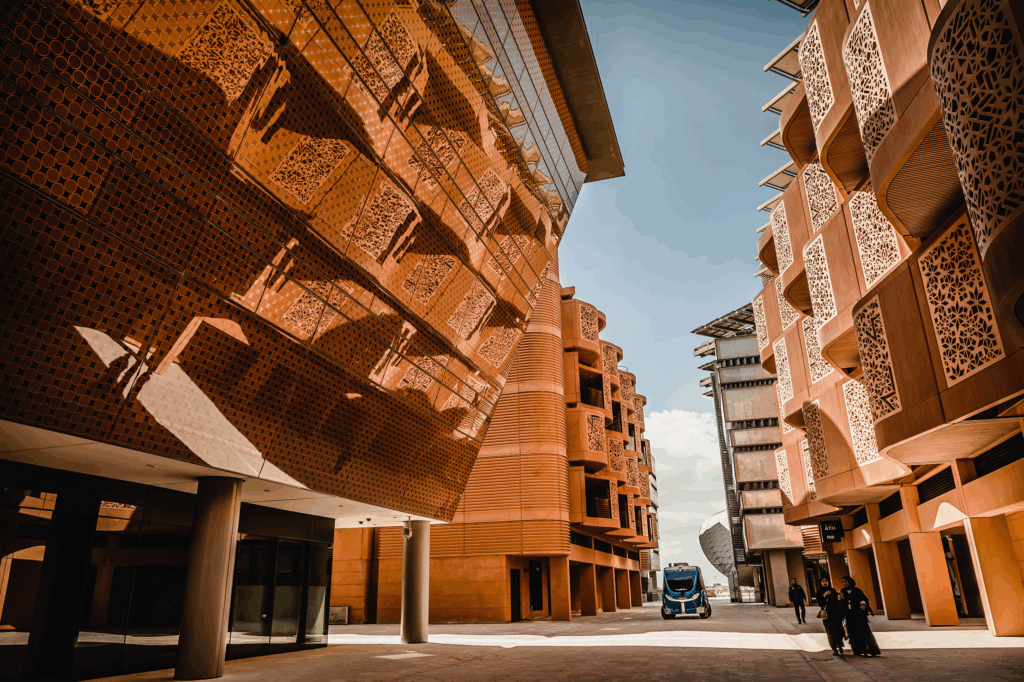

Masdar City, UAE

Launched in 2008, Masdar City in Abu Dhabi was built to prove that low-carbon cities are possible, even in harsh desert environments. From the start, Masdar integrated sustainable infrastructure: solar farms supply most of its energy, a fleet of electric and autonomous vehicles provide public transit, and buildings are designed for efficient cooling and energy use. Advanced water recycling and desalination systems, along with street orientations that maximize shade and natural ventilation, address the harsh climate. The project employed high-performance materials, passive cooling structures, and smart grids to manage energy distribution. Though scaled back from its original plan, Masdar has significantly reduced carbon emissions and energy demand, providing valuable lessons in designing for sustainability from the earliest stages. The city also demonstrates the importance of adaptability, shifting transit strategies as technology evolved, while maintaining its commitment to environmentally conscious urban design.

Singapore

Unlike NEOM or Masdar, Singapore represents a different approach, transforming an existing, densely populated city-state into a global smart city over decades. With limited land and no natural resources, Singapore invested heavily in technology, infrastructure, and forward-thinking urban planning. Its Mass Rapid Transit (MRT) system and high-density developments maximize land use, while sky gardens and green building standards (BCA Green Mark) enhance livability. The government deployed citywide smart systems, including electronic road pricing, sensor-based waste management, and open data platforms. Water scarcity is addressed through the advanced NEWater program, which integrates desalination and recycling with intelligent monitoring. Singapore’s incremental upgrades show that smart city transformation is possible without starting from scratch. Each new building or infrastructure project is a little smarter than the last, demonstrating that careful planning and technology integration can gradually create a highly efficient, resilient, and sustainable urban environment.

Songdo, South Korea

Songdo was one of the first large-scale smart cities, built from the ground up near Incheon, South Korea. Initiated in the early 2000s, Songdo integrated technology at every layer, including a fiber-optic broadband network and a central pneumatic waste system that replaces traditional garbage trucks. Video conferencing facilities are built into public areas and buildings to reduce travel needs, while LEED-certified buildings and green spaces promote environmental quality. The city is designed for walkability and energy efficiency, and ICT systems continuously monitor and optimize energy and water use. While some high-tech features have been underutilized, many aspects of Songdo, including its transport systems and building efficiencies, have succeeded. The city demonstrates the importance of public-private collaboration, showing that building a smart city requires coordinated effort among developers, technology firms, and government agencies. Songdo now serves as a “living laboratory,” influencing new smart city projects worldwide.

Across these four projects, a common theme emerges: smart cities require innovative construction practices, new materials, integrated technology, and adaptive planning. Whether starting from scratch like NEOM or Songdo, or evolving existing urban fabric like Singapore, these examples provide invaluable lessons for designing more efficient, sustainable, and livable cities. They show that smart city principles are actively being realized in concrete, steel, sensors, and code, shaping the urban landscapes of today and tomorrow.

Explore how smart construction practices are being implemented in real-world projects. Check out our blog on Concrete Construction Projects Innovating the Industry!

Build Data Centers Faster with SmartRock® Long Range

Smart Construction: How it Helps Improve Risk, Productivity, Sustainability, and Differentiation

Adopting smart construction practices provides tangible benefits for both project outcomes and overall business performance. Here, we break down four critical ways building smarter transforms construction:

Reducing Risk and Improving Resilience

- Minimizes safety concerns, delays, and weather disruptions

- Uses early detection and predictive tools to identify risks before they escalate

- Leads to safer worksites, fewer disruptions, and more resilient buildings

Boosting Productivity and Efficiency

- Improves coordination and reduces rework with real-time visibility

- Enhances scheduling and planning through data-driven insights

- Automates repetitive tasks to shorten timelines and reduce waste

Enhancing Sustainability

- Optimizes material and energy use to cut environmental impact

- Supports greener building through efficient resource management

- Makes sustainability a standard practice, not an afterthought

Standing Out in the Market

- Demonstrates innovation and digital expertise with tools like BIM, IoT, and AI

- Attracts top talent and fosters a culture of technology adoption

- Positions firms to win more business as smart city demand grows

Smart construction helps companies lower risk, boost efficiency, meet sustainability goals, and lead in a changing market. Those who embrace it aren’t just building better projects they’re building stronger, future-ready businesses.

Getting Ready for Smart City Projects

Preparing for these projects means developing the right skills, tools, and strategies now. Here are practical steps to position your team for the next generation of urban infrastructure:

Invest in Digital Skills and Training

The foundation of smart construction is a workforce fluent in modern tools.

- Training staff on BIM software, data analysis, IoT systems, and related technologies.

- Upskilling existing employees or hiring specialists in AI, data, or cybersecurity.

- Ensuring project managers can interpret dashboards and field engineers can install and troubleshoot sensors.

Many training programs and certifications are available, and younger engineers often bring tech-savvy experience. A team that combines construction knowledge with digital fluency is better equipped to succeed in smart city projects.

Embrace New Partnerships

Smart city projects often involve cross-industry collaboration. Key approaches include:

- Partnering with tech firms, startups, or municipal agencies to integrate construction expertise with innovative technologies.

- Joining planning phases early to offer construction insight while tech providers contribute their solutions.

- Building relationships with IoT and smart infrastructure vendors to jointly bid on projects.

- Understanding public-private partnerships and how to participate effectively.

Firms that adapt to these new ways of working gain a competitive edge and can contribute meaningfully to smarter cities

Pilot Smart Tech on Current Projects

You don’t need a massive smart city job to start. Consider:

- Testing AI-driven project management platforms or energy modeling tools.

- Using drones for site mapping and inspections.

- Incorporating SmartRock sensors in concrete pours to become familiar with IoT data.

Small pilots help your team gain confidence, build case studies, and demonstrate measurable improvements, such as reduced delivery time or resource savings. Many techniques like BIM coordination or energy modeling can be applied to standard projects while preparing your team for larger smart city work.

Prioritize Sustainability and Resilience

Cities increasingly demand low-carbon, climate-resilient infrastructure.

- Using greener materials, like supplementary cementitious materials or recycled steel.

- Improving waste management on site.

- Aligning with certifications such as LEED or BREEAM.

- Proposing resilient solutions, like flood-proofing or permeable pavement, to support climate adaptation goals.

Projects that incorporate sustainability and resilience are more competitive, as these are core pillars of smart cities.

Stay Informed on Smart City Trends

Smart city policies and tech are evolving rapidly. To stay ahead:

- Keep up through sites like Smart Cities Dive, which track trends like electrification and AI-enabled infrastructure.

- Monitor policies, codes, and incentives for smart technologies and energy systems.

- Track technology trends, such as 5G-enabled IoT or AI for city operations.

- Identify opportunities for expertise, like all-electric building systems or data integration platforms.

Continuous learning and adaptability are crucial for staying competitive in this dynamic field.

Design for Flexibility and Scalability

Flexibility ensures that infrastructure remains valuable as technology evolves.

- Designing modular systems that can be upgraded without major reconstruction.

- Oversizing conduits or leaving space for additional sensors and cables.

- Choosing open standards to allow future integrations or device replacements.

Delivering adaptable projects adds value to the city and enhances your team’s reputation for forward-thinking solutions.

Smart city readiness is a mindset. Embracing innovation, cross-disciplinary collaboration, and continuous improvement will position teams to lead. Emerging trends such as modular construction, robotics, and data-driven decision-making are shaping the future of urban development. Whether it’s a transit system, a smart water network, or an AI-managed skyscraper, projects will require teams capable of integrating digital intelligence into concrete and steel.

Conclusion

From wireless sensors inside concrete pours to AI-optimized mix designs and 3D-printed components, even the most traditional materials are going smart. What used to be hard hats and hammers is now paired with IoT dashboards and cloud-based models. And it’s working, delivering faster timelines, higher quality, and lower emissions.

You don’t need to become a programmer, but blending traditional expertise with digital tools is essential. The core goals of construction haven’t changed: safety, quality, budget, and speed. Smart tech simply helps us reach them better. The teams that succeed will combine craftsmanship with real-time data to bring complex, connected cities to life. The future of construction is being written today on BIM models, tablets, and IoT dashboards. The smart construction revolution is here. And those who adapt will lead it.

Want to take your construction projects to the next level? Download our free guide on Sustainable Construction!