Driver enablement is transforming how ready-mix fleets operate. As the industry battles high turnover, rising quality demands, and increasing delivery complexity, producers are recognizing that mixer drivers are more than truck operators; they’re frontline partners in quality, safety, and efficiency.

Want to take the guesswork out of concrete slump?

In this blog, let’s take a look at how to empower our drivers through training, smart tools, and real-time data.

What Is Driver Enablement in Ready-Mix Fleets?

Driver enablement means giving ready-mix drivers the training, tools, and data they need to succeed. It transforms them into quality and delivery partners, not just truck operators. With mobile apps, GPS routing, and in-drum sensors, they’re empowered to manage perishable concrete efficiently, safely, and within spec.

Why Does Driver Enablement Matter?

Ready-mix fleets face high turnover and staffing gaps. With 35% of drivers quitting annually and 68% of producers losing business due to shortages, the pressure is real. Driver enablement tackles this by improving training, support, and communication, which empowers the team you have to deliver better performance and long-term retention.

From Tools to Trust: How Enablement Works

Driver enablement gives mixer drivers digital tools, real-time data, and continuous training to make informed decisions. Mobile apps replace paperwork and radios, while in-drum sensors provide live slump and temperature updates. This approach turns drivers into proactive quality partners, boosting efficiency, safety, and confidence with every concrete delivery.

To illustrate the difference, here’s a comparison of traditional mixer operations versus a driver-enabled fleet:

| Aspect | Traditional Mixer Operations | Driver-Enabled Fleets |

| Training & Skills | – Basic Commercial Driver’s License training – Learning on the job – Little or no ongoing education | – Structured training with clear competencies – NRMCA certification – Regular refreshers |

| Routing & Communication | – Manual route planning – Radio or phone updates – No real-time optimization | – Driver apps with GPS – Turn-by-turn guidance – Live dispatch adjustments |

| Idle Time Management | – Frequent idling at plants/jobsites – Delays are unmanaged – Idling is seen as normal | – Precise scheduling – Real-time jobsite updates – Less idle, more efficiency |

As the table shows, a driver-enabled approach focuses on continuous improvement and smart technology integration.

Core Competencies Every Mixer Driver Must Master

Even the best tools are only effective in the hands of capable people. That’s why driver enablement starts with well-trained, knowledgeable mixer drivers. Ready-mix delivery is demanding, and without proper training and support, many new drivers leave within the first year.

Building core competencies gives drivers the confidence and capability to succeed:

- Safety and Vehicle Operation

Drivers must conduct thorough pre-trip inspections, safely operate trucks and chutes, and follow DOT regulations. In-cab telematics and driver scorecards can reinforce defensive driving habits and highlight areas for improvement.

- Concrete Knowledge and Quality Control

Drivers need to understand slump, temperature, mixing times, and allowable adjustments. Tools like in-drum sensors and slump meters provide real-time feedback, so drivers can deliver concrete within spec.

- Time Management and Dispatch Coordination

Drivers must plan each load within narrow delivery windows. GPS route optimization and driver apps help manage changing conditions and keep everyone updated with accurate ETAs.

- Communication and Customer Service

Drivers represent your brand on the jobsite. They must interact professionally with site crews, take instructions, and explain quality limits when needed. Mobile apps enable real-time messaging and digital ticketing, streamlining service.

When companies invest in developing these competencies through formal training, mentoring, and easy-to-use digital tools, drivers feel more prepared, more valued, and more likely to stay. The result is a safer, more capable team delivering better concrete.

Drivers as Quality Partners

In traditional ready-mix operations, quality control has typically been the job of batch plant personnel or lab technicians, while drivers were seen as simply “hauling mud.” But with driver enablement, that mindset shifts. Drivers are treated as frontline quality partners, empowered to influence concrete performance from the moment it leaves the plant to the point of placement.

Redefining the Driver’s Role in Concrete Quality

What happens inside the drum during transit is critical. Slump and temperature can change due to weather, time, or drum rotation. With tight 60–90-minute delivery windows, a mix can easily fall out of spec before reaching the site. Traditionally, a driver might rely on visual cues or a quick test on site, which is often too late to fix problems.

Drivers as the First Line of Quality Defence

Driver enablement, supported by in-drum sensor technology like Giatec’s MixPilot™, gives drivers real-time visibility into concrete properties. These sensors measure slump, temperature, and volume during transit, sending alerts to the driver and dispatch if values drift. Drivers can then act by adjusting mixing speed, rerouting for cooling, or following approved protocols for admixture or water to maintain quality before it’s compromised.

Temperature matters, too. Hot weather accelerates curing, cold slows it. Enabled drivers can adjust accordingly:

- Parking in shade,

- Adjusting water temperature, or

- Running cooling systems to maintain optimal conditions.

This insight turns them into active problem-solvers, not passive operators.

Closing the Loop Between Jobsite and QC

Enablement also includes feedback loops. Drivers can log jobsite data such as customer feedback or water added, helping Quality Control teams refine future loads. This two-way data sharing supports better decisions and more consistent, concrete outcomes. With tools and trust, drivers become stewards of quality, reducing rejected loads and boosting confidence in every pour.

Traditional concrete slump monitoring can cost you. Read more here!

Reducing Idle Time and Driver Stress

Long wait times and chaotic scheduling are two of the biggest stressors for mixer drivers. Many are dispatched early, only to sit idling at a jobsite due to delays, or spend hours rerouted through heavy traffic.

These inefficiencies, once considered unavoidable, are now solvable with a driver enablement approach that blends smarter planning, technology, and real-time communication. The payoff? Happier drivers and a more productive fleet.

The Costs of Idle Time

A major game-changer is dynamic routing. Enabled fleets use GPS tracking and route optimization to reduce idle time and wasted fuel. Rather than relying on fixed routes and radio updates, drivers get real-time turn-by-turn navigation. If traffic builds or an accident occurs, dispatch can instantly reroute the driver. These systems not only improve efficiency but also produce highly accurate ETAs. Job sites are better prepared, and drivers spend more time pouring, less time waiting.

Keeping Drivers and Dispatch in Sync

Equally important is communication. In traditional fleets, updates often happen via radio or phone, which is slow and inconsistent. With driver apps, everyone stays in sync. If a site isn’t ready, dispatch can notify the driver before they leave the plant. If a pour takes longer than expected, the driver can update dispatch with a tap. Instant messaging, push notifications, and integrated job updates reduce misunderstandings and prevent wasted time.

Predictable Schedules Reduce Burnout

Scheduling improvements also reduce driver stress. A major reason drivers quit is the lack of predictability. Enablement programs use predictive dispatching to balance workloads and prevent back-to-back late pours. Some fleets even allow shift bidding or swaps through driver apps, adding flexibility and control. These tools help drivers manage their work-life balance: a key to retention.

A Calmer Workday Builds a Stronger Fleet

Cutting idle time boosts morale. Drivers feel more productive and less frustrated when their time isn’t wasted. It also improves safety and vehicle wear. When workflows are smooth and clear, drivers focus on the task at hand and get home on time. Ultimately, enablement tools foster a more predictable, less chaotic workday and a more committed team.

Want to take the guesswork out of concrete slump?

Business Benefits of Driver Enablement

Driver enablement isn’t just good for morale; it’s good for business. When mixer drivers are trained, trusted, and equipped with the right tools, ready-mix operations see measurable improvements across the board.

From lower operating costs to stronger customer loyalty, the return on investment is clear. Here are five key outcomes:

- Fewer Rejected Loads and Quality Issues: Drivers with access to in-drum sensors and real-time data can monitor slump and temperature in transit, catching problems early. This reduces rejected loads, wasted material, and project delays. Delivering consistent, on-spec concrete builds contractor trust and minimizes costly rework.

- Higher Fleet Utilization and Productivity: Enabled drivers spend less time idling and more time delivering. With optimized routing and streamlined jobsite coordination, each truck can complete more loads per shift. This improves revenue without expanding the fleet—a key advantage in tight labor markets.

- Reduced Operating Costs: Efficiency translates into savings. Better routing lowers fuel use; smoother driving reduces wear on brakes and tires. Driver behavior incentives and monitoring tools further extend equipment life. Fewer rejected loads mean less waste, and improved retention cuts recruitment and training expenses.

- Improved Driver Retention and Recruitment: Empowered drivers feel valued and supported, and they’re more likely to stay. Tech-forward operations that invest in training, apps, and safety systems are attractive to younger talent. Enablement helps you retain your best drivers and stand out to new recruits.

- Better Customer Service and Reputation: Drivers shape customer experience. When they’re informed, punctual, and confident in product quality, customers notice. Enabled drivers reduce complaints, increase on-time delivery, and boost satisfaction. Over time, this builds loyalty and strengthens your brand.

An example is Murphy Concrete & Construction (MCC) in Wisconsin. They introduced a driver enablement and gamification app to track and reward safety, efficiency, and professionalism. This led to lower maintenance costs, improved morale, and virtually zero turnover. MCC proved that investing in enablement improves quality, retention, and profitability; a win across the board.

In short, enabling your drivers means empowering your business. The impact shows up in every pour, mile, and customer interaction.

Find out how B & B Concrete Co., Inc., transformed their ready-mix concrete operations for their drivers with MixPilot! Read the case study.

Addressing the Driver Shortage with Enablement

The ready-mix industry is facing an acute driver shortage. With an average mixer driver age nearing 47 and nearly 40% turnover each year, fleets are seeing unfilled routes, delivery delays, and missed revenue opportunities. While long-term solutions like licensing reform or broad outreach are important, driver enablement offers a practical, near-term impact.

How to Build a Culture Drivers Want to Stay In

- Start by retaining the drivers you already have. High turnover is often tied to burnout and lack of support. When companies invest in modern tools, flexible scheduling, and training programs, drivers feel more respected and stay longer. Even small improvements like replacing clipboards with mobile apps or avoiding back-to-back late pours can boost satisfaction.

- Enablement also helps attract the next generation. Younger drivers want more than a job: they want growth, tech-forward tools, and a positive work culture. When companies showcase digital dispatch systems, in-drum sensors, and clear career paths (e.g., from Concrete Delivery Professional certification to lead driver or trainer roles), the job becomes more appealing. Modern expectations require modern workplaces.

- Work culture plays a big role, too. Publicly recognizing drivers, asking for their input, and celebrating milestones fosters loyalty. Empowered drivers are more likely to refer peers and stay engaged. Culture isn’t just HR policy, it’s a recruitment tool.

- Lastly, enablement helps close workforce gaps. Efficient routing and better communication mean fewer people can cover more ground without burnout. With 97% of producers reporting open driver positions, the winners will be those who maximize the team they have.

In short, driver enablement is a force multiplier. It retains experienced staff, attracts new talent, and unlocks more performance per truck. For companies serious about solving the driver shortage, this is where the work begins.

Address the construction labor shortage. Download our guide here!

Building the Driver Enablement Tech Stack

Driver enablement is not just about changing mindsets. it’s about equipping drivers with the right technologies. This “driver enablement stack” includes digital tools and real-time data systems that help mixer drivers stay informed, reduce errors, and deliver better results. Here are the four key components of this stack and how they work together.

- Smart Dispatch and Delivery Planning Software

Modern dispatch platforms automate delivery scheduling, truck assignments, and route optimization. Unlike manual systems, they use GPS and AI to plan the most efficient sequence of deliveries. Dispatchers can monitor trucks live, identify delays, and make on-the-fly adjustments. Plant managers and even customers can access real-time delivery status through cloud-based portals. This level of transparency creates predictability and sets up drivers for success.

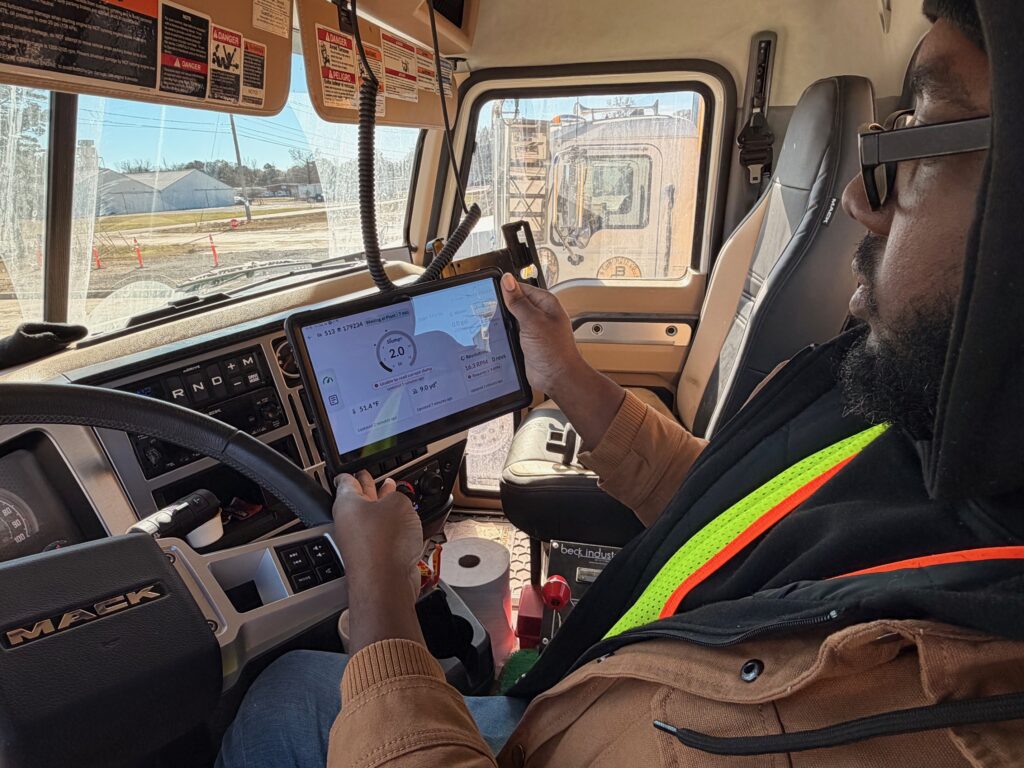

- Driver Mobile Apps for Communication and Tickets

These apps give drivers a centralized, digital hub for all job information, such as GPS directions, load details, customer contacts, and instant updates. Drivers can mark status changes like “arrived on site” with a tap and replace paper tickets with digital signatures. Two-way communication ensures drivers can easily report issues or receive rerouting instructions. Apps with voice navigation and step-by-step checklists improve safety and reduce stress on the road.

- In-Drum Concrete Sensors and Telematics

Hardware like MixPilot provides live slump, temperature, and volume data from inside the drum. These readings alert drivers and dispatch when values fall out of range, allowing immediate adjustments. Meanwhile, truck telematics collect vehicle data such as location, engine diagnostics, and drum revolutions to monitor safety and maintenance needs. Together, these tools create a “smart truck” that empowers drivers to maintain concrete quality and vehicle health in real time.

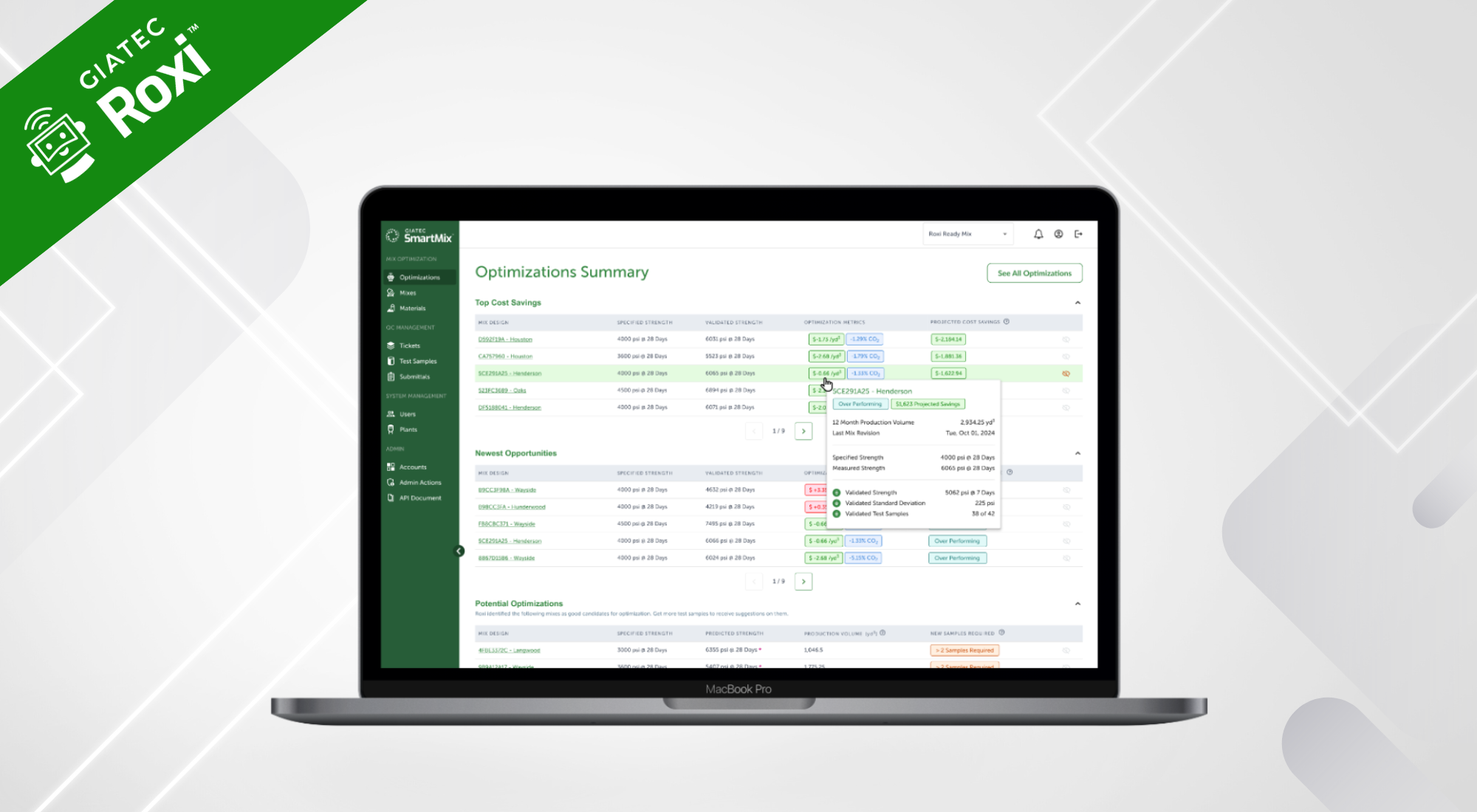

- Analytics and Quality Data Platforms

The final layer converts data into decisions. Cloud platforms can integrate sensor, telematics, and dispatch data into a unified dashboard. Managers can track KPIs like idle time, delivery turnaround, and consistency across the fleet. These insights help refine operations, identify training needs, and reward high-performing drivers through gamification features and scorecards. It also supports quality assurance by logging mix properties from plant to pour for traceability and compliance.

When integrated, these technologies form a connected, driver-first ecosystem. Dispatch systems talk to apps; sensors feed real-time insights to both drivers and management. With tools like MixPilot and data platforms, every load can be tracked, every adjustment validated, and every driver empowered to deliver their best.

Investing in this tech stack may require upfront resources, but the payoff is substantial: greater efficiency, higher-quality concrete, fewer rejected loads, and a more capable, satisfied workforce. In today’s digital jobsite, a connected fleet is no longer a nice-to-have; it’s the foundation of competitive advantage.

Conclusion

Driver enablement about giving mixer drivers the clarity, tools, and respect they need to thrive in a demanding role. When you enable your drivers, you enable your business: boosting quality, reducing waste, and creating a fleet that’s safer, smarter, and stronger. The road to a better ready-mix operation starts behind the wheel.

Empower your drivers with in-transit monitoring. Find out your ROI with MixPilot!