Concrete slump affects more than just the mix; it impacts profitability, productivity, and performance across your entire operation. Even small variations can have a ripple effect, causing delays, wasted materials, and driving up costs. Yet, traditional slump testing remains cumbersome, subjective, and highly variable. Results often come too late, forcing teams to react after issues arise rather than prevent them proactively. The lack of real-time, accurate data also creates blind spots, making coordination difficult. Additionally, producers are forced to overdesign mixes to compensate for added water that is not measured.

Want to take the guesswork out of concrete slump?

In this blog, let’s look at the four critical areas where slump continues to weigh on producers. We’ll also highlight how advanced concrete slump monitoring solutions like MixPilot™ can give producers full visibility and control.

1. Operations

Without real-time visibility into your concrete’s slump, temperature, and volume, maintaining efficiency across operations becomes increasingly challenging. For instance, loads that come out too wet because of aggregate moisture can trigger delays as adjustments move through back-and-forth communication. The same is true for loads that arrive too hot or too cold.

Lacking reliable data, adjustments are reactive and time-consuming. Returned concrete presents similar challenges. When the remaining volume isn’t known in advance, drivers must determine how to manage the leftover material as they arrive at the plant. This uncertainty slows workflows, creates delays, and makes decisions around reuse, rescheduling, or turning material to block inefficient and inconsistent.

2. Driver Retention and Training

The ready-mix concrete industry experiences high driver turnover rates, with roughly 30% of drivers being new to the industry each year. Even as they gain experience in the field, they are responsible for taking ownership of the quality of their loads. Training on slump and load management can be extensive and time-consuming. New drivers often lack the experience or reference points to confidently make adjustments or defend their loads when necessary. Without effective tools and technology, it becomes difficult to standardize training, ensure consistency, and maintain quality. This knowledge gap slows onboarding and limits the ability to scale operations effectively, ultimately impacting both operational performance and overall productivity.

3. Inaccurate Testing

Traditional concrete slump testing is cumbersome, time-consuming, and highly subjective. It is also often undocumented, creating gaps in data needed to address customer complaints or troubleshoot issues. The problem is even bigger on trips where no slump tests are conducted. In these cases, drivers rely on what they see or hear to estimate slump, introducing guesswork into a process that directly impacts load quality. Even when tests are performed, the manual process can delay decision-making and still produce inaccurate results. These limitations make it difficult to confidently evaluate load quality, respond to disputes, or identify patterns that could improve future batches. Without accurate, timely data, producers cannot be proactive, creating inefficiencies and increasing the risk of rejected loads.

Want to take the guesswork out of concrete slump?

4. Material Margins

Material margins in the ready-mix industry are critically low. To compensate for variability that cannot be measured or predicted, mixes are often overdesigned, resulting in an average of 20% extra cementitious material. This overdesign is necessary to maintain quality but drives up costs and reduces efficiency. Significant waste also comes from rejected loads and returned concrete. Without visibility into slump, temperature, or volume throughout the production cycle, producers lack the insights needed to optimize mixes and improve margins.

Limited data makes it difficult to identify trends or make informed adjustments, forcing teams to rely on conservative assumptions rather than precise measurements. These challenges leave producers unable to fully control costs and margins, with inefficiencies silently impacting profitability across every batch.

Why is MixPilot a Game Changer?

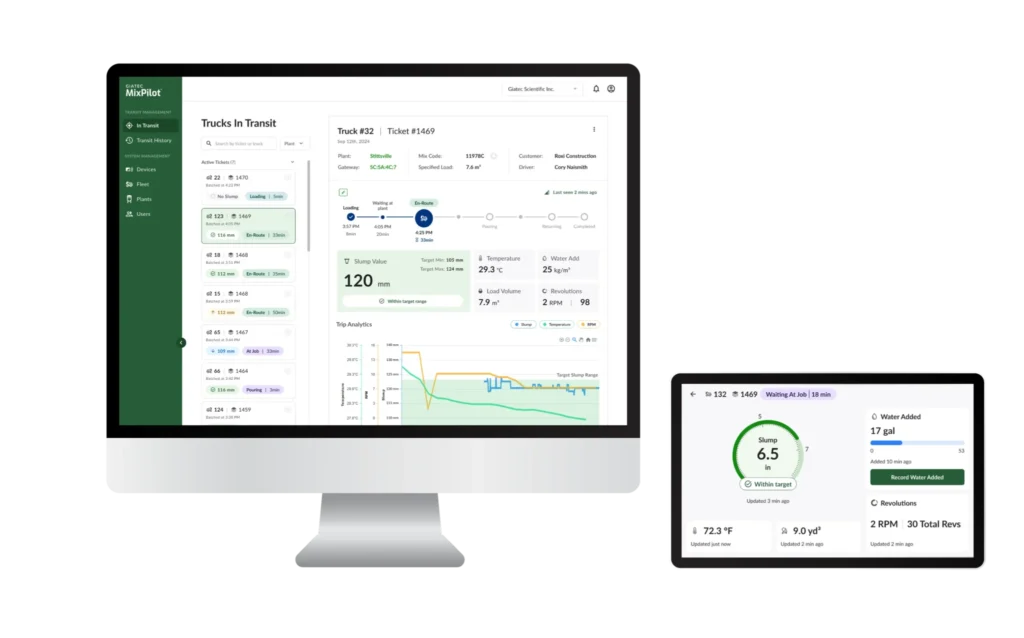

As the industry’s most advanced concrete slump monitoring system, MixPilot delivers real-time, highly accurate slump, temperature, and volume data that transforms every truck into a quality-controlled load. Installed in minutes and seamlessly integrated, MixPilot puts producers in full control with reliable insights from plant to pour.

With this real-time visibility, temperature can be controlled without holding up schedules, returned concrete can be planned for in advance, and adjustments can be made proactively. For drivers, especially those new to the industry, MixPilot simplifies monitoring with instant, automated slump readings, giving them the confidence to deliver consistent, quality concrete every time.

MixPilot also streamlines testing and quality checks, replacing manual checks with instant, reliable data every minute. This allows producers to address issues immediately, maintain consistent load quality, and reduce waste. With actionable insights throughout the production lifecycle, adjustments can be made proactively, helping protect material margins and optimize performance.

Integration with quality control platforms such as SmartMix™ further enhances these capabilities, ensuring the right data reaches the right people at the right time. This seamless integration allows producers to unlock data-driven insights, ensuring the concrete they pour is the concrete they designed, every time.

Advanced Concrete Slump Monitoring

Real-time, integrated concrete slump monitoring solutions like MixPilot are shaping the future of concrete quality control. Whether it’s enhancing workforce efficiency, ensuring mix accuracy, or enabling smarter adjustments, MixPilot empowers producers to make confident, data-backed decisions. By delivering instant, actionable insights on slump, temperature, and volume, MixPilot enables teams to save time, cut costs, and mitigate risk across their entire operation.

Ready to invest in quality for efficiency? Discover how MixPilot can transform your concrete operations with our calculator!