The Project

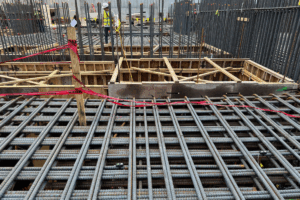

The E11even Hotel & Residences is a 64-story luxury condominium tower developed by Property Markets Group (PMG) and constructed by John Moriarty & Associates. Standing nearly 700 feet tall, the tower contributes to the Miami skyline with a blend of luxury and engineering complexity. The project features a 12-story parking podium beneath a high-rise structure constructed with high-strength concrete in its vertical elements.

To support the project’s demanding performance requirements and evolving construction strategy, Giatec was introduced as a concrete monitoring solution, providing an integrated ecosystem designed to strengthen quality assurance, improve decision-making, and increase confidence in construction schedules. Through Giatec’s ecosystem, SmartRock® Long Range sensors and the Giatec 360™ cloud-based dashboard were implemented to enable the team to move beyond traditional testing methods and gain real-time visibility into their concrete performance for this high-rise project.

The wireless sensors were deployed starting from the 39th floor to monitor concrete temperature and strength development in columns, shear walls, and deck pours through to the 64th level for quality assurance.

Turning Quality Control Challenges into Confidence

In the early phases of construction, the team was looking for a faster and more efficient way to monitor the strength and concrete quality.

Tasked to resolve these challenges, Skyrise partnered with Giatec to introduce the SmartRock Long Range system to provide in-place strength data and reduce the need for additional on-site sampling and destructive testing to maintain the pace of the project.

Using the in-place SmartRock data delivered through the Giatec 360 dashboard, the team could confirm that the concrete was in general accordance with the performance specifications. The use of real-time monitoring enabled the contractor to validate results with physical sampling techniques without delay and confidently maintain project momentum.

Eric Stern, P.E, Principal, Skyrise Engineering and Testing, LLC., stated, “In general, the construction team was impressed with the level of data, the amount of data, and the speed of data that you can get, in lieu of sifting through pages and pages of concrete lab reports.”

Full-Service Implementation and Field Performance

SkyRise Engineering managed all aspects of the SmartRock deployment, working closely with Giatec’s support team on product demonstrations, sensor calibration, installation, and daily monitoring. The Long Range gateway was mounted just beneath the tower crane cab, ensuring optimal signal coverage across active work zones.

The system’s performance exceeded expectations, even under intense thermal conditions. Stern noted prior to deployment, “One of the things we did beforehand was run a test protocol. Everybody was surprised that the equipment held up to the heat of hydration from the 12,000 PSI concrete, and that the SmartRock sensors were able to withstand that heat and keep working.” In addition, the results demonstrated accuracy within a few percentage points of traditional sampling methods.

From Quality Assurance to Industry Proof Point

While the project team did not use SmartRock data for early release on this phase, the sensors played a critical role in reinforcing quality assurance practices. In addition to supplementing lab-based testing, the data improved confidence in construction progress and helped prevent unnecessary delays and rework.

SmartRock is now being accepted by structural engineers as part of standard concrete quality control programs, reducing reliance on physical sampling. Stern emphasized, “We could prove to some of the most prominent developers, contractors and engineers that we have a new way to conduct business in Miami.”

While the use of the technology was not used on Phase I for early break release, SmartRock built the confidence required for full acceptance and is now being integrated into future phases for early break release, including E11even Tower 2, where it is projected to reduce field time by two to four hours per pour section.

The feedback from structural engineers is that they really appreciate the data, its consistency and reliability. The fact that they’re now allowing us to incorporate SmartRock as part of a standard concrete sampling and quality control process speaks volumes. In other words, we’re reducing physical sampling and replacing it with digital sensors. It’s a swap!

— Eric Stern, P.E, Principal, Skyrise Engineering and Testing, LLC

A Scalable Solution for Vertical Construction

This project established that the SmartRock Long Range can be scaled and successfully managed across tall and complex structures.

The combined efforts of Giatec’s support team and SkyRise were essential to the project’s success. Their partnership, along with the real-time insights from SmartRock, ensured smooth coordination and quick responses to field conditions. SkyRise provided full-service deployment and on-site management, while Giatec’s support team offered responsive assistance across time zones. Together, they helped simplify operations and decision-making. Stern also highlighted how quickly Giatec modified the system based on field feedback, continuously improving the software and workflows to better meet the project’s changing needs.

Leading the Way Toward a Digital Future

The E11even Hotel & Residences project demonstrated how Giatec’s SmartRock Long Range solution can be scaled and successfully managed across tall and complex structures. Withreal-time concrete monitoring technology, SmartRock can address quality challenges, improve transparency, and streamline decision-making.

While the industry still depends on physical sampling, Stern noted seeing a rising demand for quicker, more connected digital workflows. He believes SmartRock and similar technologies are vital to the industry’s future but notes that broad adoption will take considerable effort in education and building trust.

By using SmartRock on the project, the team proved that access to data-driven insights could strengthen their QA/QC process. As such, they are setting a precedent for future high-rise construction projects in Miami and beyond.

Since this project began, SmartRock Long Range has a new look! It features the same great technology, but with a fresh style.