At Giatec’s Concrete Tech Summit in May 2025, Mark Masotti, CEO, and Alex Hanmore, Manager of Concrete Technologies at AlterBiota made a compelling case for transforming how the industry approaches aggregate testing and the huge potential it poses for optimizing the fresh and hardened performance of concrete. Their message: it’s time to digitize aggregate testing.

Want to take the guesswork out of concrete slump?

When paired with platforms like Giatec’s SmartMix™ and MixPilot™, digitalAggregate™ becomes a critical piece in a much bigger picture, one where optimization starts at the source and extends all the way to the pour, supporting consistent concrete workability.

Concrete’s Blind Spot

Traditional aggregate testing is time-consuming, low frequency, and limited in what it can measure. Most labs focus on aggregate size, using outdated but standardized methods like sieve analysis that only determine one of three dimensions.

As shared by Mark, “With the sieve analysis, it would work perfectly if concrete aggregates were spheres. However, they are anything but […]. It’s the same idea that a marble and a pencil would be retained on the same sieve”. This disconnect between lab testing and field performance isn’t just theoretical, it has real cost implications. Cement overuse, rejected loads, slump variability, and water mismanagement, all stem, in part, from poor aggregate visibility.

This is where digitalAggregate makes a difference. Using advanced image segmentation and processing of images collected from both offline and inline sources (pile and chute respectively), producers can now capture detailed morphological data (size, shape, angularity, texture) in real time. This can be done through a smartphone for imaging a grab sample or stockpile, or through inline sensors installed directly at the batch plant, providing truly real-time, batch-specific data on aggregates.

The result is accurate, high-frequency data without the manual burden. A single grab sample analysis takes less than a few minutes. Inline systems capture aggregate data for every batch automatically.

Building a Connected Concrete Ecosystem

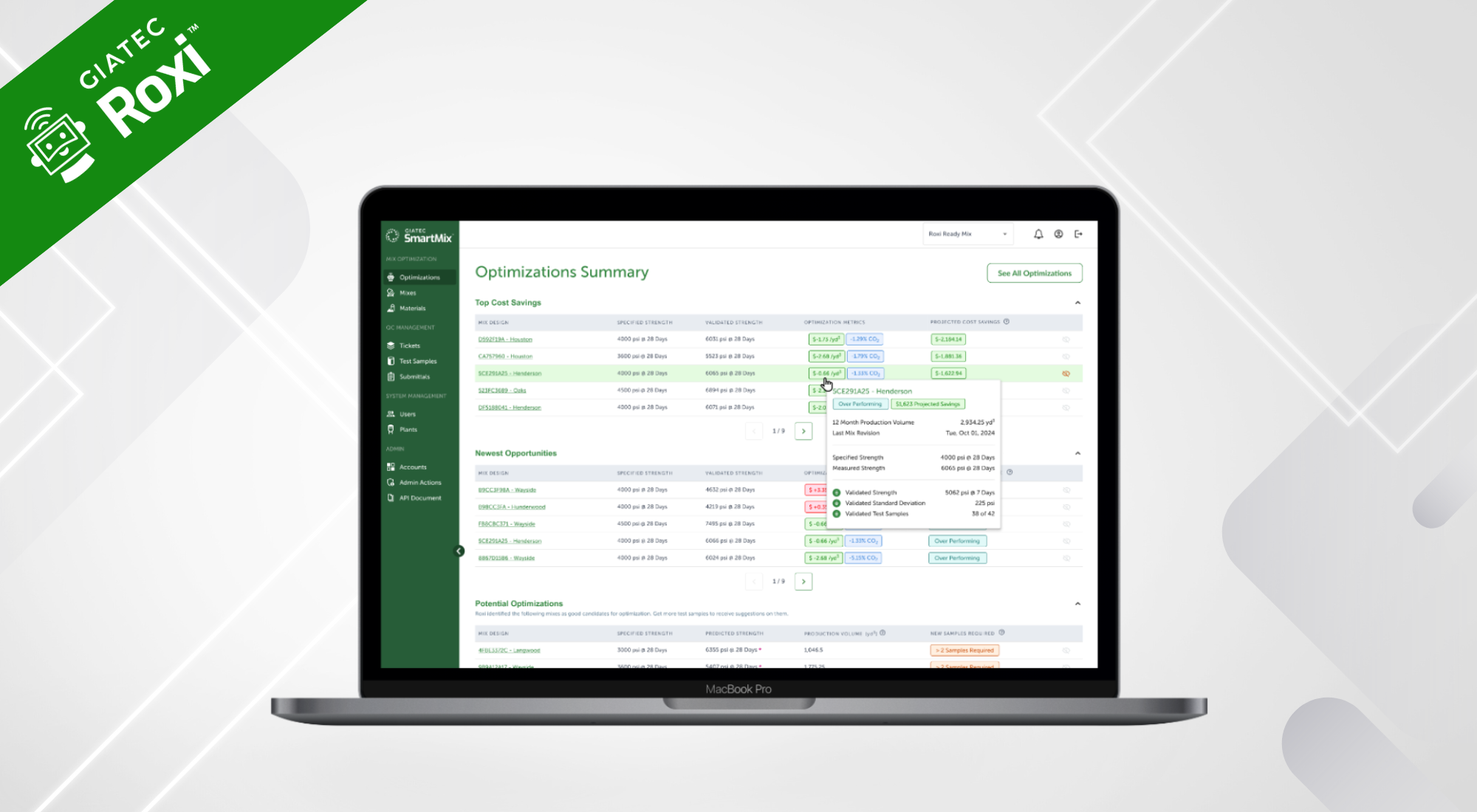

DigitalAggregate doesn’t just streamline lab work. It’s designed to integrate with systems like SmartMix, the leading AI-powered concrete quality control software.

Together, these tools unlock full visibility across the concrete lifecycle:

- DigitalAggregate provides granular input data at the point of batching.

- SmartMix brings it all together optimizing for cost, CO₂, and performance.

- MixPilot monitors the consistency and workability of each batch, including the influence of truck mixing energy, and correlates it with batch-specific digitalAggregate data.

This connected workflow creates a powerful feedback loop. If aggregate shape or texture changes, MixPilot detects the change, then SmartMix can recommend adjustments. And because all three systems speak the same digital language, teams can act on the data, not just collect it.

One of the most compelling trials showed that aggregate roughness alone, without changing gradation, could reduce the concrete’s slump by half. With that level of variability, producers need more than batch averages, they need batch-specific data to make informed decisions.

Learn more about how digitalAggregate integrates with SmartMix. Read here!

Real-Time Aggregate Data

AlterBiota’s inline system is currently being piloted at multiple sites across North America, including Tomlinson Ready Mix. These installations are validating how digitalAggregate data correlates with slump measurements from MixPilot and optimization outcomes in SmartMix.

The early signs are promising:

- Imaging-based gradation curves show very low error rates compared to traditional sieve results

- Texture Data (e.g. roughness) helps to predict water demand and adjust paste volumes

- Shape data (e.g. flatness, angularity) enables more accurate predictions of concrete workability, helping producers reduce paste volumes without sacrificing finishability.

And most importantly, this data can now be collected automatically, in real time, and fed directly into the systems customers are already using.

In the near term, producers can expect reduced QC effort, fewer rejected loads, and better control over material inputs. Long term, the vision is even bigger: fully connected quarries, batch plants, and job sites sharing data to fine-tune concrete quality from the source.

The Future of Concrete Workability and Mix Optimization

While Digital Aggregate is still gaining traction, the technology is maturing quickly. Fine aggregate analysis, recycled aggregate recognition, and even cleanliness scoring are in development. These features will further enhance how data flows into platforms like SmartMix, bringing new levels of precision to mix optimization, performance tracking, and mix submittal automation.

Ultimately, this is about control. The more you know about your materials, the less you have to guess. That’s the promise of connected quality control, and it’s already being delivered by the Giatec ecosystem.

Ready to take your concrete operations to the next level? Explore our full range of solutions and see how real-time data can give you end-to-end visibility and control over your operations.