Artificial intelligence (AI) is widely used to solve problems in industries like finance and healthcare, however, the construction industry has generally had a slower rate for adopting such new technologies. This prompted Giatec to launch Roxi™, the world’s first AI program for concrete testing. While Roxi can revolutionize the concrete industry by improving concrete testing methods, the construction industry still faces many problems such as on-site activity monitoring and scheduling. Fortunately, in the past few years, several companies have emerged to tackle these problems using AI. Take a look at some of the most exciting AI solutions that are disrupting the construction industry.

IoT Devices

Internet of things (IoT) devices are small objects that can wirelessly transmit data. They can be placed on materials and equipment in construction sites to collect data, which can be utilized to teach/train AI algorithms. For example, Giatec’s SmartRock® sensors can be embedded in concrete to collect temperature data points. Roxi is revolutionizing the concrete industry by using machine learning (a branch of AI that focuses on using data to make decisions) to detect anomalies in these data points and verify concrete strength test results. This is done through training these algorithms using data collected from over 6500 projects in 45 different countries. Embedded devices can also collect data about workers and equipment. For instance, Kwant.ai is a start-up that is creating wearable sensors that can be placed on equipment like hard hats, belts or vehicles to collect data. Their AI program analyzes this data and predicts project delays and safety incidents.

Site Activity Monitoring

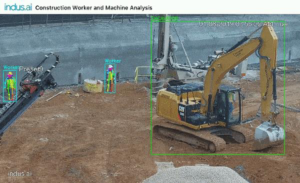

Construction sites can be chaotic with many different activities being performed simultaneously. Companies like INDUS.AI, Atollogy and Smartvid.io are using cameras and computer vision models, which are machine learning models that analyze images and videos, to monitor construction sites and get insights about activities. INDUS.AI and Atollogy have developed platforms that can predict safety violations and material arrivals and departures by detecting workers and vehicles. For example, their computer vision models can count how many workers are on a jobsite and determine if they are wearing hard hats and safety vests. They can also detect trucks that enter and exit jobsites to track materials. In addition, computer vision models can predict when equipment, like cranes or excavators, are operational so project managers can reduce their idle times.

Another solution, Vinnie by Smartvid.io, uses video and image data to predict safety risks, track productivity, and detect defects such as cracks in tunnel walls. Smartvid.io also harnessed the power of voice recognition technology. When a user uploads a field documentation video to their platform, which is integrated with Procore, it uses voice recognition models to tag the videos based on keywords that it hears in the video. Their platform quickly organizes images and videos based on objects detected and keywords heard.

Construction Schedule Optimization

Completing a construction project in a timely and cost-effective manner can be difficult. A study by McKinsey & Company showed that large construction projects typically have schedule overruns of 20% and can have cost overruns of 80%. Project managers must schedule tasks, such as pouring concrete or placing columns, but there may be millions of possible scheduling strategies to complete a construction project; this is too much for a human to consider. Fortunately, ALICE Technologies has created a platform that uses AI to help project managers schedule construction projects. It uses a project’s building information modeling (BIM) data and constraints to simulate many different scheduling strategies and provides the user with optimal strategies to save time and money. The platform has been utilized to plan several construction projects including highways, airports, and hotels. In case studies, users reported that they saved up to 69 days on their construction projects using the platform.

Augmented Reality

Augmented reality (AR) combines real-world environments with computer-generated objects. Computer vision models can help AR programs detect surfaces and predict the 3D locations of objects from videos. It has many applications from video games to medical training, but now companies like Astralink are bringing AR technology to the construction industry. Their app helps workers find discrepancies between their BIM models and their actual jobsites. When a user views their jobsite through a tablet, Astralink’s app overlays 3D digital blueprints onto the jobsite in real-time. They use computer vision models to compare the actual state of the jobsite to the blueprints and detect mismatches between them. This can prevent errors early in a construction project and reduce rework.

Autonomous Vehicles

Over the past few years, numerous companies have collectively reported spending over $16 billion on self-driving vehicle research. While fully autonomous vehicles are not street-legal yet, they are already being deployed on construction sites. Since the construction industry is experiencing a labor shortage, autonomous machines can help construction projects run smoothly. This is one of the factors that motivated development of the first commercially available autonomous vehicle system for the construction industry. They are retrofitting dozers, excavators and compact track loaders (CTLs) with AI guidance systems, including GPS and Light Detection and Ranging (LiDAR), so that they can operate fully autonomously. These vehicles use computer vision models along with sensors to navigate around jobsites, dig trenches and excavate foundations.

Autonomous vehicles can also be utilized to design layouts for jobsites. Layout plans are critical because they ensure every worker understands the specific details about what needs to be built. However, maintaining a good layout can be challenging because it often requires constant communication with various teams on the jobsite and needs to be updated as conditions change. To address these issues, Dusty Robotics has built a self-driving robot that can draw layouts of jobsites. Their robots can drive around jobsites and map out structures like walls or columns to create layouts. Their platform synchronizes BIM models with the layout and uploads them to the cloud so all workers can build on the latest documents.

Click here to learn more about self-driving robots!

AI is revolutionizing the concrete and construction industries by providing disruptive solutions to long-standing problems. It can detect activities on jobsites to keep workers safe and track materials. It can help project managers schedule their construction tasks to prevent schedule and cost overruns. Many tasks can be automated using self-driving vehicles and errors can be found with AR technology. In the coming years, AI will likely have a stronger presence on construction sites, however, it cannot replace workers. AI solutions are tools that complement the skills and expertise of workers to ensure construction sites are safer and more efficient.

Sources

Kwant.ai

INDUS.AI

Atollogy

Smartvid.io

ALICE Technologies

astralink

Built Robotics

Dusty Robotics

Mckinsey & Company