Surf™

Surface Electrical Resistivity Testing

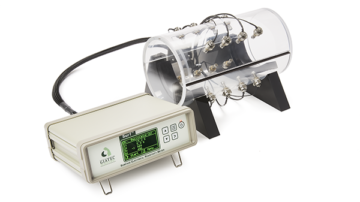

Laboratory device for measuring the surface electrical resistivity of concrete

Surf™

Surf is a laboratory device for testing the surface electrical resistivity of concrete based on the four-probe (Wenner-Array) technique. Surf. These measurements are used to estimate the resistance of chloride penetration in the concrete. This shows the qualitative relationship between the rapid chloride penetrability test (RCPT) and the surface electrical resistivity of concrete. This surface resistivity meter can also be used for durability-based quality control of concrete and for monitoring the service life design of a structure.

| Single Measurement Time | 1.5 seconds |

| Testing Time | (8 measurements) |

| Measurement Channels | 4 |

| Frequency | 13 – 100 Hz |

Reading Range

| Reading Range | Frequency range | Accuracy |

| 0.1 – 100 KΩ.cm | 13 – 100 Hz | ± (0.1+1%) |

| 100 – 1000 KΩ.cm | 13 – 100 Hz | ± (1+1%) |

| Part No. | Item | Description |

| 900107 | Surf™ – Comprehensive Package | Surf™ unit, 100×200 mm (4″x8″) Sample holder, Power adaptor, USB cable, PC Communication software, User manual, Conductive gel, Verification kit, Additional Set of conductive pads, Hand-held probe |

| 900037 | Surf™ – D100 Full Package | Surf™ unit, 100×200 mm (4″x8″) Sample holder, Power adaptor, USB cable, Communication software, User manual, Conductive gel, Verification kit, Additional Set of conductive pads |

| 900030 | Surf™ Device | Surf™ unit, Power adaptor, USB cable, Communication software, User manual, Verification kit |

The following replacement parts and accessories are available upon request:

| Part No. | Item | Description |

| 900100 | Hand-held Probe | For measurement of surface electrical resistivity on flat surfaces of large concrete samples/elements |

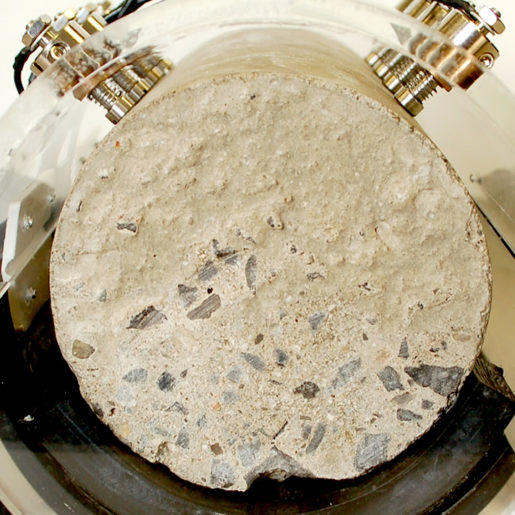

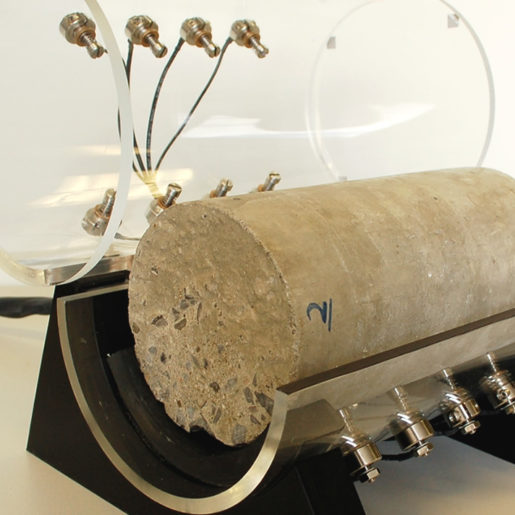

| 900031 | Surface Sample holder-D100 | 100×200 mm (4″x8″) sample size, Conductive gel, Additional Set of conductive pads |

| 900032 | Verification Kit | High and low range dongles to verify the performance of the device |

| 900038 | Conductive Gel – High Viscosity | 250 ml bottle |

| 900033 | Test Cable | Four-point connection cable with alligator clip |

| 900034 | Contact Sponge Set | 16 pcs |

If you are testing saturated surface dry specimens (SSD condition), there is no need to use wet sponges. But, for dry specimens, you must use either wet sponges on the connection tips or the conductive gel provided with the device.

Giatec Surf utilizes a patented technology to automatically measure the surface resistivity 8 times around the cylindrical concrete specimen using its four channels of 4-probe arrays. The PC software then generates the required reports according to the standard specifications.

The current version of Surf has been designed for laboratory applications in the durability-based quality control of concrete. An accessory is under development for Surf that enables this meter for field applications as well.

The four input channels of Surf device can be connected to accessory cables for customization of test-setup for surface resistivity measurement from the surface of concrete elements (e.g. crack detection under load) or be embedded in fresh and hardened concrete for the monitoring of setting and moisture transport, respectively. Giatec’s scientific team will be happy to assist you with your particular research project application.

Now’s your chance to start building smarter. Get started today to see if you qualify.