Eliminate Concrete Testing Delays

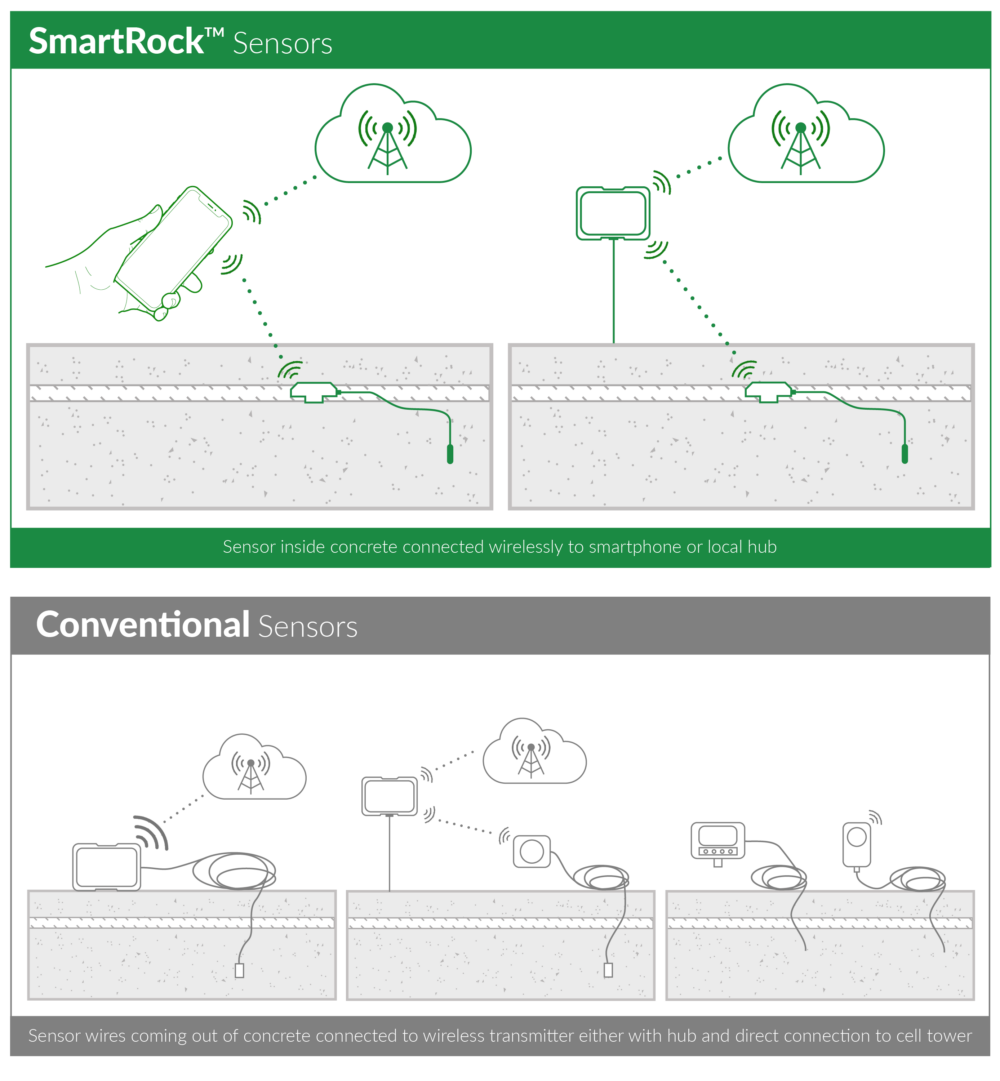

Fully embedded on the rebar with no wires or testing labs required, this easy-to-use, hassle-free sensor allows for quick decision making onsite and prevents unnecessary setbacks.

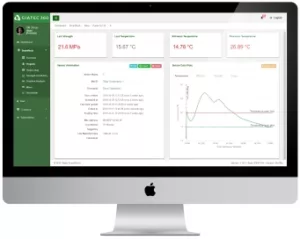

Improve Data Accuracy

The maturity method, used by SmartRock, is approved by ASTM and ACI as an accurate and reliable test for measuring concrete strength onsite for more accurate results than field-cured cylinder breaks.

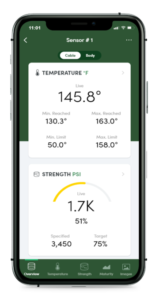

Know the Status of Your Pour 24/7

With real-time data and 24/7 remote monitoring capabilities, confidently check the status of your pour and get notifications anytime, anywhere, on any device.