With traditional concrete strength testing practices, that is the use of cylinder break tests, the reliance on third-party testing labs is detrimental to a project’s timeline and budget. While wired data loggers can save some time, the data collected must still be analyzed off site by an experienced individual. Technology like SmartRock, which are non-destructive wireless maturity sensors that collect and analyze data on-site and in real-time using a smart device, can significantly reduce a project’s timeline.

Explore 12 Futuristic Technology Trends Solving Concrete's Biggest Challenges.

Traditional Destructive Concrete Testing Can Harm your Concrete

A common practice in the construction industry is measuring strength by testing field cured concrete cylinders. This method is used to determine concrete strength at various stages during the first week after the concrete has been poured. The cylinders are then taken to a lab where they undergo a break test. If results show that the specimen has reached 75% of its designed strength, the structural engineers can move forward with form removal and post-tensioning. However, this process comes with many risks.

- Information is gathered from the field-cured cylinders and later crushed in a compression machine.

- Cylinders are not necessarily representative of the in-place strength of the concrete and can therefore result in low breaks.

- Results may be affected if cylinders are improperly prepared, handled, or tested.

- Transportation and handling of specimens can lead to loss of structural integrity.

- The curing conditions of the specimens are not the same as the in-situ concrete.

- It costs to have a technician cast, collect, deliver, and test the specimens.

- Samples get sent to the lab to be tested, and contractors have to wait for the results.

- Additional labor costs due to uncertain project scheduling as a result of lab report delays.

- Financial costs due to late completion time on projects.

On the other hand, maturity, a non-destructive approach to testing concrete, allows you to estimate the early-age and compressive strength of in-place concrete in real-time. Using wireless maturity sensors ensures quick, instant, and reliable data, with the advantage of saving costs and staying ahead of your schedule! Maturity is a value that represents the progression of concrete curing, it considers concrete temperature and curing time. The goal is to determine a relationship between maturity and strength for a specific mix. As a result, mix calibration is required to implement this concept in a project.

Reduce Project Costs

There are significant economic benefits to using maturity on a construction project. Cost savings are not only observed on large projects, small projects can gain from the use of this method. Overall, significant advantages can be seen through the ability to save time by conducting critical operations more efficiently, such as removing formwork, post tensioning, and opening pavement to traffic in a more efficient and timely manner. In every industry, particularly the construction industry, time is money. There are initial costs associated with the use of maturity which include the maturity meters and calibration. However, there are more important cost savings that can result from the implementation of this method.

Wireless mobile-based maturity sensors, such as SmartRock, have been developed as a more efficient approach to concrete strength/maturity monitoring. Using these wireless mobile-based maturity sensors can therefore significantly reduce the time and thus the cost of concrete quality control.

Calculating Cost Savings on a Job Site:

In a typical 40-storey high-rise concrete structure, 200 maturity meters are needed for real-time strength monitoring. Each SmartRock wireless maturity sensor helps save 20 minutes of installation time and 40 minutes of reading/analyzing time.

SmartRock save(s) an unbelievable amount of time and money for the contractor…and takes the maturity method to the next level. – Walter Flood III

If the data from each maturity sensor is collected on three separate occasions by a technician, with an hourly cost of $50, the total labour cost savings in the quality control of this project approach would be $23,300. These savings can easily justify an investment of $17,000 for wireless SmartRock maturity sensors.

In addition, costs are also significantly reduced as a result of the maturity method, which eliminates the need to break samples. This alone accounts for $30K to $50K in savings.

A family-run business, Flood Testing Laboratories (FTL), faced several challenges with their usual maturity monitoring systems. After using SmartRock maturity sensors, it allowed them to remotely access and share data in real-time on any mobile device, and embed the maturity sensor in concrete with no vulnerability from construction activity. In addition, SmartRock allowed them to “save an unbelievable amount of time and money for the contractor” said Walt Flood III, Secretary and Treasurer of Flood Testing Laboratories.

Find out how Flood Testing Laboratories saved costs on their project! Learn more here!

In this way, wireless maturity sensors, such as SmartRock, work in favor of the contractor by providing an easy installation process and easy data collection by being “able to get individual sensor data using Bluetooth if you don’t have the Internet – and then upload the data later for sharing with the project team,” said Walter Flood III.

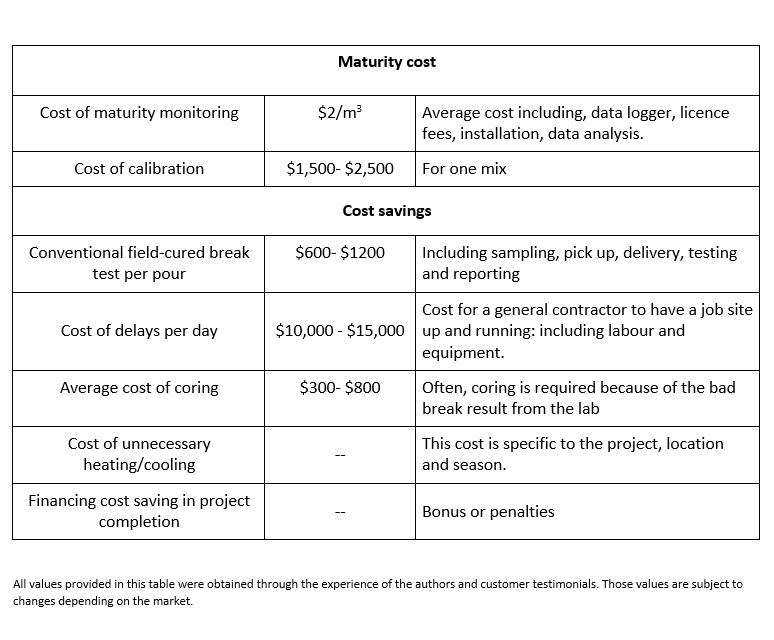

This table shows a breakdown of the initial cost involved in the implementation of the maturity method and possible cost savings on a project. The price ranges given are subject to change based on the type of maturity meter and the quantity of maturity meters or sensors purchased. Additionally, the cost of cylinders and site operation varies greatly depending on the location and type of project. As there are significant differences in terms of pricing between different maturity meters on the market, the cost of maturity was averaged and taken as an additional cost per concrete volume.

More importantly, optimizing the construction schedule by providing real-time strength monitoring enables project managers to save up to a day on early formwork stripping for each floor. Even in projects where the break test is mandatory, the concrete maturity testing can be used to determine the optimum time at which the field specimens should be sent to a lab for analysis.

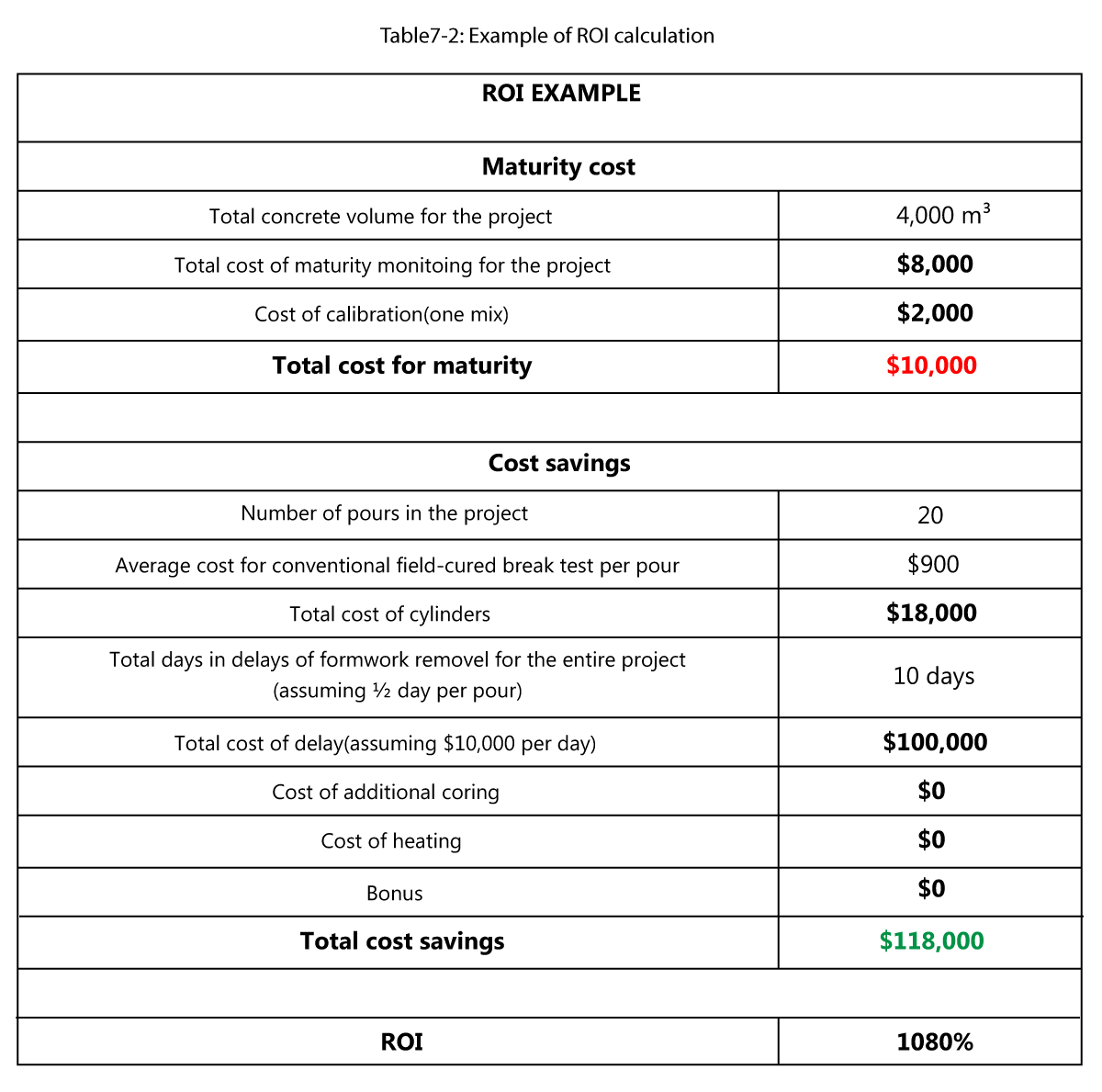

In this example below showing costs savings with an ROI calculator, typical average values were used and cost savings were conservative. The reader is encouraged to develop his/her own ROI to gain a better understanding of the cost savings based on the specifics of his/her own project4 . To put things into perspective, if the time savings are as small as one day for the entire duration of the project, the cost of maturity is already offset.

Calculator Your ROI savings with our calculator Learn more here!

**Editor’s Note: This post was originally published On March 26, 2016 and has been updated for accuracy and comprehensiveness.