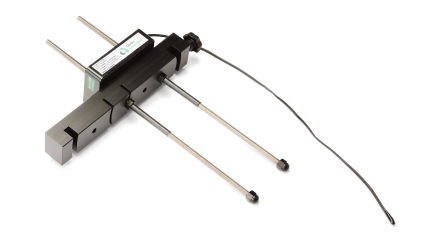

SmartBox™

Wireless Concrete Sensor for Resistivity and Temperature Monitoring

Measure & monitor electrical resistance, temperature, & setting time of fresh concrete

Product discontinued: SmartBox is now a Giatec legacy product

Product discontinued: SmartBox is now a Giatec legacy product

SmartBox™ is a wireless sensor for measuring and monitoring the electrical resistivity and temperature of fresh concrete. Monitoring these properties provides insights regarding the water content of your mix, giving you a good indication on the setting and hardening time of your concrete. This data is recorded by the SmartBox device where it can be downloaded in the mobile app (available for Android).

This method of resistivity measurement is not standardized and is suitable for various research applications. However, AASHTO TP 95-11 – Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration provides the test standard for surface electrical resistivity measurement.

| Reading Range | 1 – 3000 Ω |

| Measurement Frequency | 10 KHz |

| Accuracy | ± 2% |

| Measurement Time | <1s |

| Battery Life | Up to 3 months |

The battery life on a single charge is about 3 months for basic data log under room temperature.

The standard log follows this schedule:

First 24 hours: every 5 minutes

Next 72 hours: every 1 hour

After that: every 6 hours

We also have custom log which provides a fix log interval in minutes (1 min to a couple of days). This can be changed by the user in the app menu.

The device can store 1024 data points in the following format:

Time | Date | Temp (C) | Resistance (ohm)

10:20 | 10/02/2015 | 23 | 789