Revolutionize the Concrete Industry

with Smart IoT Testing and AI Solutions

with Smart IoT Testing and AI Solutions

Experts revolutionizing the construction industry

Stay on the cutting edge of concrete tech

Save the date and join us at future events and conferences

As mass concrete is now an essential part of the construction industry, it is important to consider the different factors that affect its quality and strength gain. When designing and monitoring a mass concrete mix, contractors must take special consideration to the maximum temperature that the mass element concrete will be subjected to. The maximum temperature of concrete is typically in the core of the mass element. However, in insulated thinner elements this could occur near the insulated surface. Moreover, for regular mass placements, the peak will typically be reached within the first 48 hours after the pour. Although, this could vary according to the size and placement schedule. The maximum concrete temperature corresponds to the concrete temperature placement in addition to the heat rise. In this blog, we will learn about other temperature-related challenges when working on mass concrete.What Is Delayed Ettringite Formation (DEF)?The main concern surrounding the allowable maximum temperature of concrete is the issue of delayed ettringite formation, typically referred to as DEF. As ettringite has limited temperature stability, it does not form at high temperatures. This is an issue when concrete reaches high temperatures. Furthermore, when high heat generation occurs the potential for volumetric expansion at later stages…

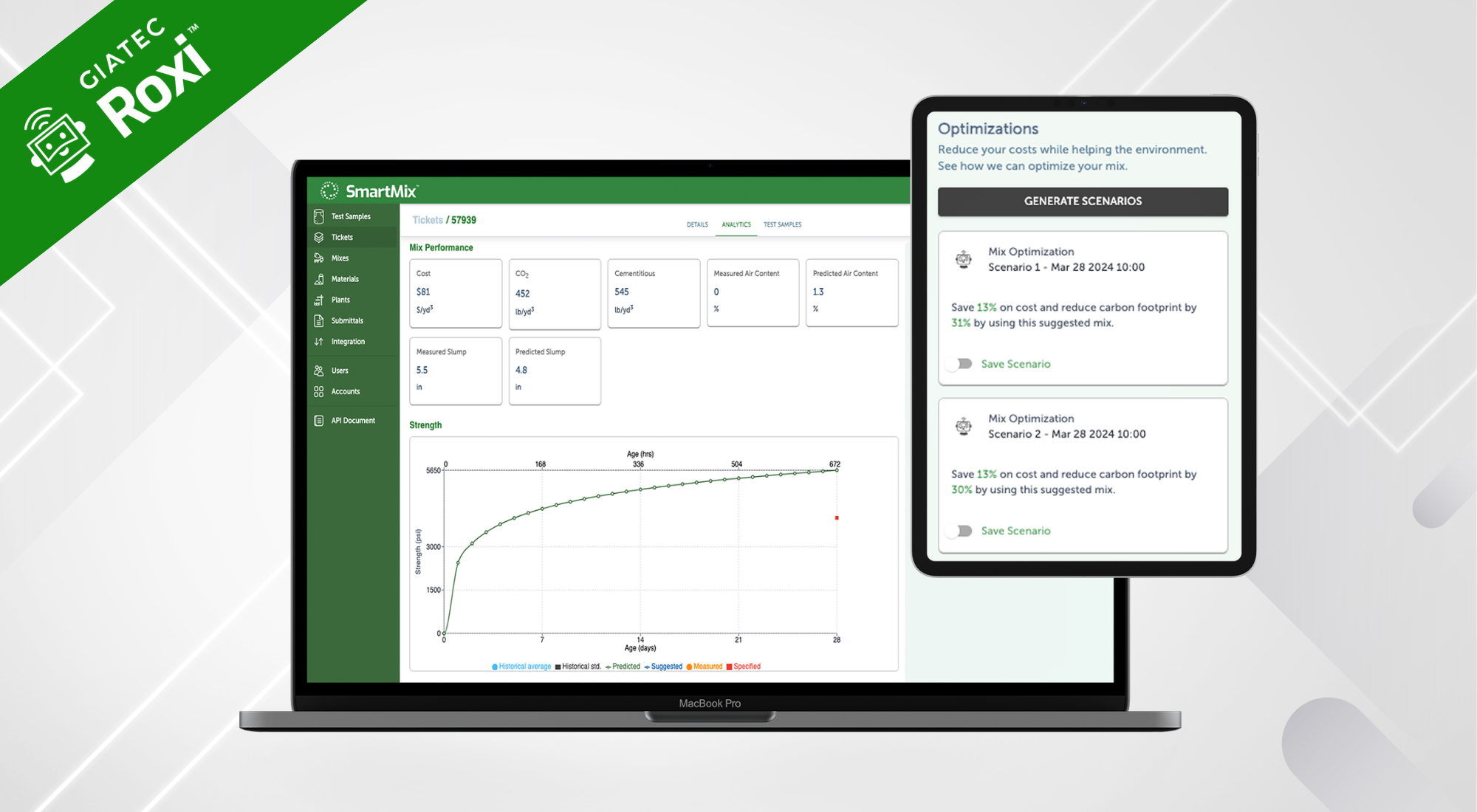

The concept of artificial intelligence in concrete is frequently discussed, yet its practical application and effectiveness remain elusive. Despite the buzz, there seems to be a lack of understanding of what industry challenges can be solved with artificial intelligence and how. Hence, there is a need to shed light on its practical implications, bridging the gap between theoretical concepts and tangible solutions. As a pioneer in artificial intelligence in concrete, Giatec® interviewed quality control professionals from over 20 companies throughout North America. The purpose was to identify primary challenges impacting their businesses and areas where artificial intelligence could effectively apply. The interviews revealed four key issues consistently present across companies of all sizes and market demands: Understanding these challenges better, it became evident that they all converge into a central issue: overdesign. Rooted in a complex interplay of industry dynamics, overdesign leads to excessive material usage, increased costs, and environmental waste. Moreover, it contributes to inefficiencies in concrete production, hindering progress toward sustainability goals and impeding overall industry advancement. Tackling overdesign is essential not only for cost reduction and resource conservation but also for driving innovation and competitiveness in the concrete industry. This is where Roxi™ and Giatec’s SmartMix™ come in; offering…

If you want to evaluate and select from the plethora of concrete temperature thermometers available in the market, this is the right blog for you. Before we dive into suggesting some of the best concrete curing thermometers we have come across, let’s go over a few essential questions. Learn in this blog about the importance of testing for concrete temperature, why it may prevent structural damage, and how opting for the correct concrete thermometer may enhance and simplify your project. Concrete Temperature: Too High or Too Low? The ASTM C1064-86 prescribes that concrete temperature must remain between 80.1oF – 95oF or between 26.7oC – 35oC. However, this can change according to project specifications. If the concrete mix is poured at a higher internal temperature, it runs the risk of encountering several problems. One of those is that your concrete could crack due to quick and premature evaporation. Alternatively, pouring the concrete mix at a temperature lower than 25oF could make the concrete freeze. This could result in multiple types of problems, including the concrete becoming severely brittle. All in all, if your concrete temperature is too high or too low, your project is vulnerable to damages that are time-consuming, expensive, and simply avoidable. Click here to read more about why concrete temperature testing is important during extreme weather! Commercial Concrete Thermometers Below, we review a few concrete temperature thermometers that may be ideal for implementation in your next project. SmartRock® The concrete testing device manufacturer Giatec offers…

Visit our careers page to learn about our award-winning culture and our open positions.