Since the commercialization of the maturity method, there have been important advancements in monitoring and computing technologies such as a simple thermocouple for concrete, wireless sensors, manual data entry, cloud sharing systems, and more.

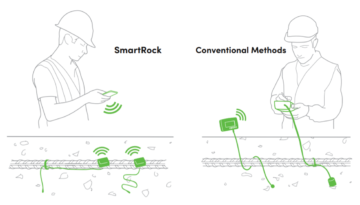

When deciding between wired or wireless loggers to measure the temperature and strength of your in-situ concrete, it is important to take into account the type of data you’re collecting, the ease of collecting data, and on-site handling of the sensors.

Watch this video on YouTube

What Is Concrete Temperature Monitoring?

One of the most important steps in the construction of a concrete structure is monitoring the temperature of your slab after placement to ensure proper curing of the in-situ concrete. This is especially true during extreme weather conditions when the mixing and curing of concrete are subject to different environmental elements. If freshly poured concrete is exposed to temperatures that are too high or too low, or if it isn’t preserving enough moisture for the process of hydration to take place, the concrete’s strength development will be compromised. These conditions can also cause thermal cracking. For this reason, closely monitoring temperature variances in your concrete slab during curing is vital to ensuring the strength, quality, and durability of your structure.

Read More About Thermal Cracking Here

Wired Systems – Thermocouple and Data Logger

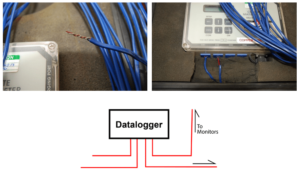

Simple datalogger and thermocouples monitoring

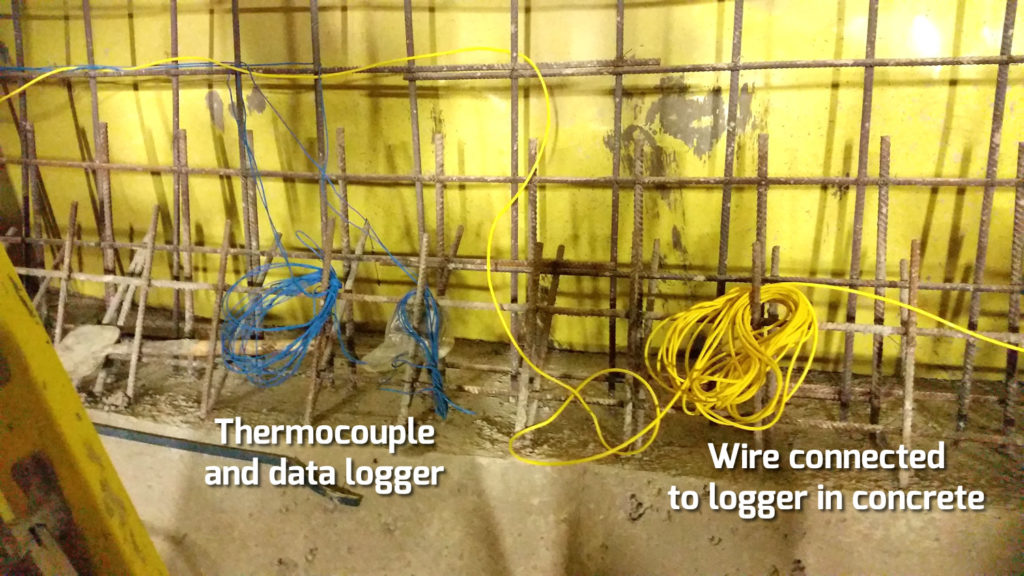

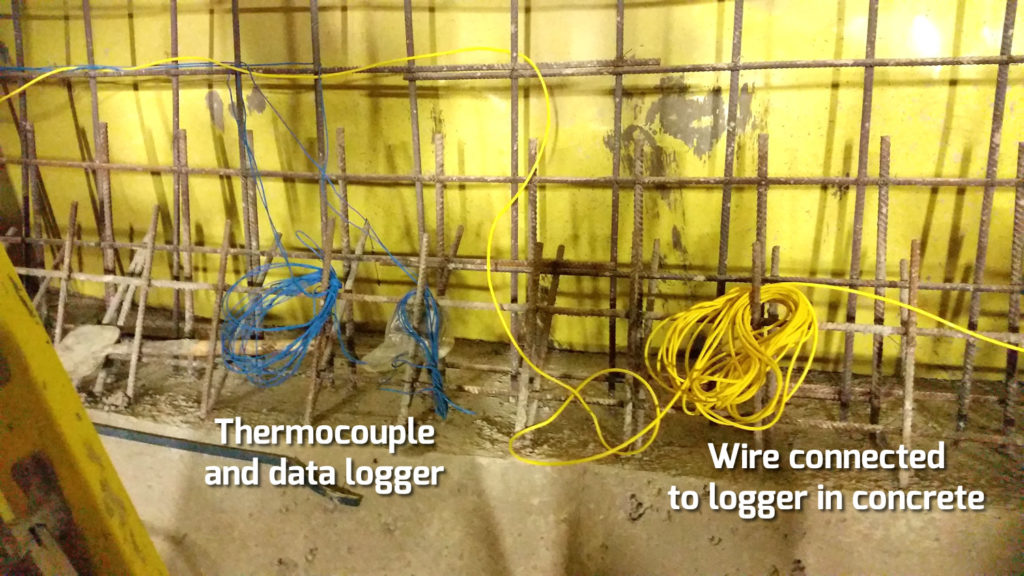

The most primitive approach to measuring temperature is using a thermocouple for concrete which is a device that measures and monitors temperature. The end of the thermocouple is placed within the formwork prior to the pour and wired outside of the formwork. Depending on the type of system, thermocouples are typically attached to a data logger which is used to record the temperature at certain time intervals. An even more rudimentary approach can be taken where no recording of a measurement is made. In this case, data analysis is done manually to determine concrete strength, which is very labor-intensive.

Upgrades to such systems have been focused largely on the storage capabilities of the temperature data history within the sensors’ internal memory. To retrieve this data, a worker connects the data logger to the sensor. This approach is widely used today and, with the help of technological improvements, it allows easier data gathering and sharing.

The majority of commercial devices available for measuring temperature and maturity have long wires that need to be installed prior to the concrete pour and extended to a secure and accessible location. This can be a major drawback of the technique because of the unconventional work environment that is a construction site. The device’s cables can easily be damaged during, or after, the pour, especially during the placement and finishing stages. Additionally, the data logger needs to be protected or kept in a secure place for later access.

What Is a Wireless Concrete Temperature Sensor?

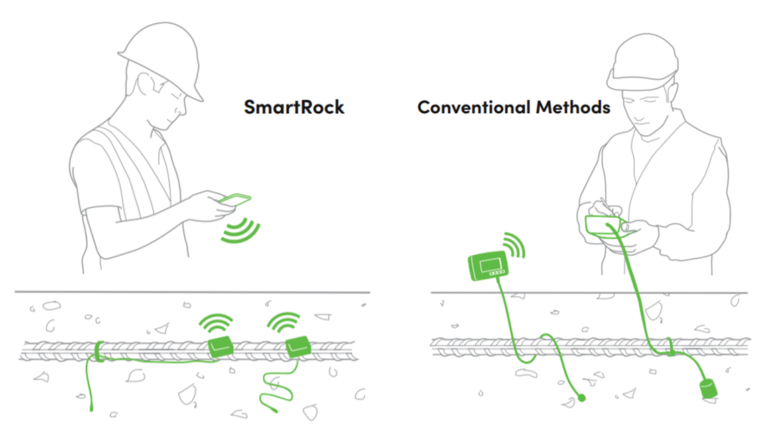

Alongside upgrades to temperature/maturity monitoring systems’ storage capabilities, there have been game-changing developments in sensor design, creating systems that can now be fully embedded in the concrete. Sensors/loggers (such as SmartRock®) can be installed in the forms prior to the pour and temperature wires can be extended to the appropriate locations within the concrete form. Once the concrete is poured, the sensors and wires are completely covered and no system components are exposed out of the concrete. Data is collected using wireless communication through a smartphone application. This application performs automatic maturity and strength calculations (as long as a calibration curve is provided) and the information can be conveniently shared to team members for easy collaboration and data viewing.

The main limitation of this approach is the maximum allowable distance between the sensor and the surface of the concrete. Concrete can block wireless signals and loggers usually need to be placed within a certain distance from the surface to ensure connectivity. To address this issue, sensor cables come in different lengths to accommodate different temperature monitoring needs.

SmartRock, Giatec’s wireless concrete sensor, is a small wireless device used for monitoring concrete temperature and strength. Unlike traditional wired concrete data loggers, SmartRock is fully embedded in the concrete and does not require a physical connection in order to transmit data.

What Is Concrete Maturity Monitoring?

When we talk about concrete maturity, we’re referring to the non-destructive, ASTM-certified approach to testing concrete that gives you accurate estimates of the early-age and compressive strength of in-place concrete.

The maturity method estimates concrete strength based on concrete temperature and curing time. In order to implement this concept in a project, you need to perform a one-time concrete mix calibration. The goal of the calibration is to determine the relationship between maturity and strength for your specific concrete mix.

With SmartRock, the temperature history, along with a calibration curve of your slab is used to calculate the real-time strength of your concrete based on the concept of maturity (ASTM C1074). This information is used to produce an analysis of the temperature and strength of your concrete, which is then transmitted to your SmartRock mobile application, and updated at regular 15-minute intervals. With real-time results, contractors can optimize the heating process, decrease energy costs, and save time in their project schedules by knowing precisely when they can move on to subsequent construction operations such as formwork removal or post-tensioning.

Learn More About the Maturity Method Here

Why Switch to a Wireless Device?

One of the biggest advantages of SmartRock is that it is completely wireless. This means you no longer need to purchase a separate costly data logger, look for wires under blankets, or worry about damaging or cutting wires. In comparison, wired systems require a data logger to be connected to a thermocouple in order to retrieve temperature data. Then, this data must be taken to a lab where an expert can analyze the information to determine the strength of the in-situ concrete. In addition to high labor costs, there are several technical inefficiencies that often occur when using wired temperature and strength meters:

- Wires sticking out of concrete often get cut on construction job sites. Construction workers try to keep the site clean and if they are not aware of the temperature monitoring tests, they may cut the wires for safety reasons, etc.

- Permanent data loggers (in the case of embedded thermocouples), have to stay on the jobsite at all times. These expensive devices can easily get damaged when exposed to humidity (e.g. rain) or can experience physical damage due to impact on-site.

- When monitoring temperature in various spots on their grid, workers often gather all wires in one location for ease of access. However, this can create difficulties in properly identifying and labeling wires, resulting in incorrect data collection.

- Moreover, the assembly of thermocouples requires careful attention to detail. If not assembled properly, wires can cross over in the plug and cause errors in readings.

- To perform a differential analysis using thermocouples, you need to install multiple thermocouples throughout the mass element. Compared to SmartRock’s dual temperature monitoring which creates and analyzes two temperature data points per sensor, thermocouples are inefficient for differential analysis. By going wireless with SmartRock, you can save time in installation as well as in analyzing data.

Wireless, mobile-based temperature sensors and maturity meters (such as SmartRock®) are a game-changing development in the concrete industry. In addition to reducing labor cost associated with concrete testing, these wireless systems can significantly improve efficiency in fast-paced construction projects.

Learn How Wireless Sensors Can Help You During Cold Weather Concreting Here

*Editor’s Note: This post was originally published in May 2016 and has been updated for accuracy and comprehensiveness.

3 Responses

felicidades nuevamente muy interesante, agradecere mayor informacion de productos en español.

Trabajo area infraestructura vial (caminos puentes y estructuras de hormigon armado)

Felicitaciones pueden enviarme mas informacion del o los productos.

Eduardo Yañez

+56 9 84298488

Hi Eduardo, thank you for your interest. To get in contact with one of our sales representatives, please fill out a request a quote form here.